What has changed Indian Railways during the last 30 Years?

Indian Railway has traveled a long way since 1980-81 and certainly a fantastic journey of ups and down. I was associated with this journey of Indian Railways from the year 1977 and till 2014. It is now most appropriate to jot down ‘what’ has gone into making of it to meet the challenges of the present level transport demand. Indian Railways is a gigantic and monolithic organisation, and it is a tough call to identify technological and managerial input that transformed the Railways.

During 2011-12 it has hauled 969 Million Tonnes as compared to 196 Million Tonnes during 1980-81. Similarly, during the same period, the sub-urban traffic grown from a level of 2000 to 4377 million passengers and main line traffic from 1613 to 3847 million passengers. There cannot be a simple mathematical modelling to simplify and help narrating the story. It is but natural for anyone to explore curiously and check for himself the decisions which have paved way for almost quintuple of loading and doubling of passenger traffic performance. It is important to note that a long term decision generally takes around 10-25 years to implement over such a large system and there is always a contribution of large many decision makers at the helm of affairs. There were periods where personality oriented management worked but not lasted long. I have identified 15 such decisions which transformed it with successful implementation over Indian Railways. The present post is “What has changed Indian Railways during the last 30 years’ and will be followed by later post on

1. What technologies tried but failed with cost implication?

2. What technologies not fully development to help Railways?

3. What technologies Indian Railways will be wishing for?

I request for your comments and suggestion to improve, add, subtract on the post.

Click on the + sign on the left of the topic to read more about it.

Gauze Conversion

Project Uni-gauge aims at changing the entire IR network into Broad Gauge and is one of the most ambitious and far-reaching endeavors the Indian Railways has ever undertaken. The need for this was to bring in uniformity in the network and to avoid breaking journeys, complications in track and other infrastructure design, for efficient use and easier acquisition of rolling stock and to cut overhead by having to keep up only one set of uniform systems throughout the country. Broad Gauge was chosen for obvious reasons: It was the most prevalent gauge and the widest, which meant larger coaches and wagons which again will mean more freight, space, speed, , carrying capacity and stability in turbulent weather.

It all started in February 1971 when the railways announced that all new lines would be constructed as broad gauge only and that the existing meter gauge would be progressively converted to broad gauge to achieve uni-gauge. But the conversion speed was slow due to the non-availability of resources.

In 1975, a decision was taken to upgrade the meter gauge system, selectively, as an alternative to gauge conversion. But the break of gauges still hampered development and its advantages could not equal those of broad gauge and failed to attract people and investments. A lot of criticism was done earlier when a route selected was not having much traffic & were selected for political consideration basically on Southern Railways. At that time at least half of SCR ant SR was on MG. It was lobbied by the propagators of the MG system to upgrade the MG system than convert in BG as standard gauge was quite successful in other countries but the then MR Jaffer Sharif had its way.

This led to an announcement of policy decision of Uni-gauze to expedite the conversion work, which had progressed at a very slow pace for forty years. The project Uni – gauge was launched in 1992 and it was made a high priority project placed before the Parliament. It was aimed at selective conversion of meter gauge/narrow gauge lines to broad gauge in a phased manner based on considerations of capacity requirement, developmental potential and on strategic considerations.

Priority lines for conversion from meter gauge to broad gauge were identified from the view of operational requirements and to help the development of the backward areas.

For each route, a techno-economic study was done to decide the approximate cost of conversion and the return on capital. An action plan was formulated for conversion of 13,117 km. of meter gauge/narrow gauge lines out of which 6,000 km was targeted to be completed during the eighth five-year plan and the rest during the ninth five-year plan. Indian Railways took up a policy for Project Unigauge in 1992 to convert selected routes for conversion into broad gauge. The salient features of the policy include:-

- To take up the conversion of lines to develop alternative BG routes obviating the need for Doubling of existing BG lines on these routes.

- To establish a BG connection to ports, industrial centers and locations having potential for growth

- To take up the conversion of lines required on strategic considerations.

- To minimize transshipment and to improve wagon turn around by avoiding delays at transshipment points.

- To carry out the conversion of lines as per the above policy at least cost, yet providing a standard of service not lower than what the rail users were getting.

Since the width of broad gauge passenger carriages is wider than the earlier ones, the gap between the platform and carriage may cause problems. Either the gap may be too large and thus unsafe, or broad gauge rolling stock is likely to hit the old platforms. Narrow tunnels and bridge of the old meter gauze may need to be widened, strengthened and raised for broad gauze broad gauze if need arise. Also, sharp curves of the old meter gauze may need to be realigned for broad gauze. All these aspects are to be taken care of in gauge conversion projects

One meter gauge and four narrow gauge tracks on which heritage trains run in hilly regions will not be converted to broad gauge. These are Darjeeling Himalayan Railways, Kalka-Shimla Railways, Ooty Nilgiri Mountain Railwys, Matheran Hill Railway and Kangra Valey Railway. A table below gives the size of the project undertaken by the Railways since re-organisation of Railways-

| 1951 | 2010 | 2012 | ||||

| Route Km | % of Total | Route Km | % of Total | Route Km | % of Total | |

| Broad Gauze | 25258 | 47 | 52808 | 82.5 | 58300 | 89.4 |

| Meter Gauze | 24285 | 45 | 8473 | 13.2 | 5212 | 8.3 |

| Narrow gauze | 4300 | 8 | 2734 | 4.3 | 1500 | 2.3 |

Conversion from Vacuum Brake to Air Brake System

The braking system prevailing over Indian Railways till early 80s was predominately Vacuum Brake system involving application of brake with the destruction of vacuüm. Braking effort through the vacuüm braking system is not enough to control heavy hauls and passenger stock requiring frequent stop and starts. Therefore, heavy haul of WAT-KIR section and Electrical multiple units working in sub-urban were only conceived with air brake system. Vacuum brake system was having following limitations which were putting a big question mark on sustained improvement in rail transport-

- Braking effort was limited to destruction of vacuüm of 50Cm of Hg requiring larger size brake cylinder still with the limitation of braking effort. Load per train was restricted to around 3600T as compared to present level of 5500T (with scope to increase it further) with air brake.

- Delayed late start of a train due to difficulty in attending vacuüm leakages at maintenance depots. There were many incidences when a train could leave the yard, even after 24 hours of detention with as many as 3 crew changes during detention.

- Hose pipe getting disconnected en-route resulting loss of time in the midsection

- Delayed application of brake on the train

A decision was thus taken to convert the existing wagon and coaches to air brake and electrical/diesel locomotive to dual brake system because in the intervening period, both air and vacuüm system will prevail. All workshops, major yards and electric loco sheds were involved in this conversion work.

It is also important to mention that when introduction of new technology involves support of large workforce, pitfalls are also there. The pitfalls were even of the level of a disaster. There were many incidences of poor brake power in the train observed after the start of the train due to

- Air pressure created in the locomotive, but not brake-van and train started with nil brake power. Continuity test was introduced.

- Brake and Feed pipe got interchanged resulting conditional braking

- Brake pipe isolating cock operated by miscreants making rear part train brake ineffective

Training, counselling and standardization etc. were organised to arrest the wrongdoing and finally succeeded.

Development in Signalling System

Signalling system streamlines transport system. It helps in maintaining a minimum distance between two trains depending on braking distance and maximum permissible speed. The Signalling system shall be such that it shall make sure safety as well as not to retard train motion, ensuring the utmost number of trains are run in the division.

Indian Railways Corporate Plan (1985-2000) assigned top priority to the technical up-gradation of the signalling and telecom organizations. The Planning Commission in its IX Plan identified the strengthening of line capacity of the Indian Railway system as the main thrust area. The Plan in its investment strategy observed that the highest priority for taking up new projects should be given to projects, which augment the capacity of the Railway system in the high density corridors, apart from investments needed for ensuring safety and reliability of services. There are 7146 railway stations spread over Broad, Meter and Narrow gauze and signalling work involves mostly BG stations. Up gradation of signalling system is also undertaking along with gauze conversion and railway electrification also.

Modern signalling and telecommunication systems help in achieving these twin objectives of augmentation of line capacity at comparatively lesser cost and at the same time improve the safety and reliability of services. The main objective of modernization of signalling and telecommunication system on Indian Railways, thus is

- To improve safety by providing advanced safety devices such as track circuiting, block proving by axle counters, auxiliary warning system, and so on

- Axle Counters are electronic devices employed for detecting presence of a vehicle on a defined length of a Railway Track. This can also be utilized as a replacement for conventional track circuiting even in locations where steel sleepers are used. Axle counters also help in the reduction / elimination of block operation time, thereby contributing to increase in line capacity.

- In Indian Railways, Axle Counters are mainly used for block proving (Section of Railway track between two adjacent stations is called block section. The process of proving that there is no vehicle in the entire length of block section is called block proving.). The Khanna Accident Inquiry Committee, in its Report (1998) recommended that Block Proving Axle Counters should be installed section-wise and not propagate out to several segments in a random and haphazard way.

- Following types of signalling are employed on the Indian Railways.

- Two aspect lower quadrant signalling (LQ).

- Multi-aspect upper quadrant signalling (MAUQ).

- Multi-aspect color light signalling (MACL).

LQ and MAUQ are now disused. MACL is the most reliable type of signalling and predominantly in use over Indian Railways. Colour light signals with powerful and penetrating light offer better visibility and drivers are able to sight them from far away and act upon their indication. Also, these types of signals are more dependable and involve less care. Initially incandescent lamps were provided and now being replaced with LED lights which provides added benefit of reliability of burning hours, visibility and energy saving.

- The automatic warning system is to control the speed of the train automatically depending on the aspect of the signal ahead. This was introduced in the Mumbai Suburban system, but could not progress further. This is done by transferring the aspect of the signal by using track-side mounted equipment to the moving vehicle and manipulating the braking system if the loco pilot does not ensure speed control after pre-warning. With the developments in digital technology advancing so fast, that by the time Indian Railway decides to zero down on one technology, it changes resulting reversal of the earlier decision.

During the year 2001, Anti-collision Device using GPS technology was very much sung about, but had to be thrown away after spending vast money. Train Protection Warning System (TPWS) is under installation and trial between Delhi-Agra route of NCR. But now Train Collision Avoidance system is under evolution. It is stated that the cost of installing TCAS (fixed and on rolling stock) is about 10-15 Lakh/Km. Keep your finger crossed about its implementation.

Status of implementation as on 31st March 2012

Color Light Signal: 5391, LED lit signal: 4773, BPAC: 3410 Block sections, Track Circuiting: 29201 and Data logger: 4773

- To provide cost effective solutions to increase line capacity by introducing systems such as Centralized Traffic Control (CTC), Automatic Block Signalling, Intermediate Block Signalling (IBS), etc.

- System of train working mainly used on the Railways is known as block system. This scheme is founded on the principle of maintaining a fixed minimum space interval between trains on a segment. The types of system for train working in the Indian Railways are Token/ Tokenless Instruments, One Train Only System, Intermediate Block Signalling and Automatic Block Signalling. The minimum space interval in the absolute block system is fixed by the distance between two stations and capacity of the route depends on the longest distance between two stations. By providing Intermediate Block Signalling between the two stations which are longest apart, the capacity of the route improves to the next maximum block distance. In case of an automatic block system, the space interval will be governed depending on the inter-signal distance and braking distance. Till 31st march 2012, Indian Railways has provided 397 IBH and 2286 RKM of Automatic Block System. Due to safety constraints, Automatic Block system is now being discouraged.

- To achieve operational efficiency through modern signalling systems such as Panel Interlocking, Route Relay Interlocking, etc.,

- Earlier, signals and points at most of the stations were mechanically operated from 2 cabins, at either end of a station, or from a central cabin. With the use of electrical signalling equipment such as panel interlocking (PI), Route Relay Interlocking (RRI), Solid State Interlocking (SSI), etc., there is no limit on the distance up to which points and signals could be operated from a centralised location. SSI is the most modern interlocking system. It is a microprocessor based interlocking and provides better reliability and consumes less power than PI/ RRI. Till 31st March 2012, Panel interlocking or SSI and RRI has been implemented on 4614 and 257 stations.

- This has helped in reducing the time taken for line clear, operation of block instrument and route setting for reception and dispatch of train. This time was adding to the running time of the train in the block section, thus, severely hampering the sectional capacity.

Replacement of wooden to concrete sleeper

With the start of Chipko Andolan in 1970 and turning into a ban in felling of trees in 1980, the timber availability for making wooden sleepers dwindled. Modernization of track with the introduction of the Long Welded Rail (LWR) and need of heavier track structure for running high speed track was felt around 1975 a committee of Chief Engineer, Director/RDSO and Commissioner of Railway Safety CRS was appointed in 1975 to suggest the measure to upgrade & modrenize the track. Based on the recommendations, a track modernization cell was created in the headquarter office with the creation of the post of Chief Track Engineer. Lastly, Indian Railways decided to introduce concrete sleeper after protracted field trials. Even though concrete sleepers were introduced as early as in the 1890s, but as usual, found much delayed application over Indian Railways. The most important advantages with concrete sleepers are

- Do not rot like timber and unaffected due to termite

- The extra weight makes the track more stable

- Gauze remains fixed. Gauze on wooden sleepers get disturbed due to loosening of the key

- No fire hazard which was very common when steam locomotives were in operation

- Longer life than wooden sleepers

- Less maintenance means less cost for you

- Date of manufacturing can be moulded with the concrete itself.

But is not without few disadvantages

- Concrete sleepers tend to shatter when the wheel hits the sleeper during derailment where as wooden sleeper has the flexibility to absorb the shock.

- Due to higher weight, it is difficult to replace when damaged during derailments or maintenance

- Initial cost is high

- Manual maintenance is near impossible and calls for change to mechanized maintenance.

The first ever concrete sleeper plant, a German made (M/s DYCKERHOFF & WIDMANN) plant started in the year 1977 in Northern Railway Allahabad and was finished in the yr 1982. It was the first ever concrete sleeper plant of the country that provided specialized concrete sleepers. Its manufacturing capacity was 3 lakh sleepers per year. Design for Concrete sleeper for turnout was developed in 1986. Concurrent evolution of concrete sleeper for level crossing, Switch Expansion Joint (SEJ) etc. also started.

The most important operational advantage gained is reduction in the derailment due to gauze disturbances.

Complete stop to ad-hoc promotions and ensuring intake from open market as per norms and improving training infrastructure

During 80s, promotions were mostly ad-hoc and the system of selection and suitability was not in place. Recruitment through RRB was very occasional and dealt more of a drive. There were seniority disputes followed by court stay order whenever a selection was ordered. With ad-hocism in manpower development, the staff morale was also at is low. Educational standards were at its miserable and difficult to absorb new technologies with confidence. There was resistance from all corners even for the introduction of computerization. The awareness of new technologies among new entrant was lacking and also their training to meet the challenge. Induction of qualified personnel has eased this situation.

A decision was taken something 1995 banning the ad – hoc promotion and the situation changed significantly with selection and suitability examination done on schedule. There is hardly any seniority dispute now, the way it was prevailing over Indian Railways during 80’s. This was also one of the reason for staff discontentment.

Training infra-structure improved with 30% incentive on the basic pay to encourage officers and inspector to join faculty. But need base training and sparing of officers and staff (involved with maintenance of assets) is still at issue. There is a certainly a lukewarm response on part of the Indian Railway management in ensuring need base maintenance after deliberated field assessment of training need. Just ensuring infra-structure does not satisfy the need.

Information Technology

Information technology is the application of computers and telecommunication to collect, store, and process, retrieve, transfer and control information in the context of business, services to humanity, etc. Computer has the vantage of a job doing in milliseconds which otherwise will take hours if performed manually. Telecommunication with facility of automatic transfer of data and interface with user friendly software has the potential to perceive management challenges made easy. IT potential has been inducted very slowly with period spanning a quarter of a century. A new organization called Center for Railway Information System (CRIS) created in the year to manage IT need but struggled a lot for networking and implementation all over Indian Railways. Nevertheless, no one denies its impact in passenger amenity, train operation and assisting decision making process. Important software which has contributed significantly in making the performance data on tips are

- Passenger Reservation system, Unreserved Ticketing System and Internet Reservation has helped in making reservation and cancellation quite comfortable.

- Freight Operation and Information system – There has been a longstanding demand of Indian Railways for transparency in sharing of information to give the customers an upto-date business-like environment. An idea originated in the year 1986 to take advantage of Information Technology to efficiently and effectively manage the processing of information The objectives are

- Convenience and Transparency to Customers

- Optimum Utilization of Resources

- Handling of Commercial and Operational aspects of Rail and Freight Movement

- Better Decision making tools

- Help for better logistics management

Rake Management System, Terminal Management System, MIS reporting, Rake Allotment/Allocation system (RAS), Terminal Pipeline Management System, Domestic Terminal management system for CONCOR are some of the features of FOIS. Visit http://www.fois.indianrail.gov.in/Enquiry/Enquiry.jsp?Input=Q_OutStandingDemandsInput.jsp to navigate the features.

- Coaching Operation and information system – It provides complete information about coaches in service, maintenance, periodical overhaul, average speed, punctuality on minute to minute basis etc. A screen shot of the features is given below:

- Automatic Train Charting – Every train after its start of journey is continuously charted in Divisional Control office and monitored for its running. Initially charting is done using different color pen and scale. All performance parameters were calculated manually. With the introduction of automatic train charting system, only train timing for each is entered as reported by the station on physical recording the time is entered and train is charted automatically. It is possible to record the time automatically from data logger installed at each station owned by Signal and Telecommunication department of Indian Railways and charting is done with controller only watching it.

- Crew Management System – Crew of a train consists of Loco Pilot, Assistant Loco Pilot and Guard. Crew is the costliest of manpower assets and therefore calls for proper utilization with adequate rest at home and outstation for his safe working. This has helped in getting rid of manual upkeep of information in registers. This has called for installation of signing in and off instrument at each booking office and interlinking together with data updating taking place continuously.

- Material Management System and e-tendering has helped in making the information of any material across board, an essential need for material management with all relevant information about it. This has improved decision making process. E-tendering has again helped in implementation of transparent system of procurement reducing processing time, fare deal and availability of information with ease.

- National Train Enquiry System – Information technology has contributed significantly in this field. It used to be a horrible experience when one has to wait for the train at station and likely arrival forecast changed many a times during the announcement. No look at the latest website of CRIS on National Train Inquiry System (NTES) and get the train information with a click of mouse. http://enquiry.indianrail.gov.in/ntes/. One can view the important features of the website on the screen shot.

Even though Indian Railways is having a dedicated organisation called ‘Centre for Railway Information System’ (CRIS) but there are many of Indian Railway functions having huge financial implications, but not yet having centralized implementation of any suitable pan-Railways software. These are

- Maintenance Management System

- Energy and Fuel Management System

- Common Platform for Office management involving sanction of leave, TA Bill, Issue of privilege pass, file tracking system, e-mail etc.

Communication has helped in improving sectional capacity. During 80’s, the target time for the loco pilot to communicate with the control in case of any failure was within 30 minutes and if the section is cleared within 90 minutes is considered to be a good job done. Now it takes only 5 minutes and clearance within 30 minutes. This could be possible with the provision of wireless communication Walkie and Talkie provided to the crew of the train for communication between loco pilot, guard and station staff.

There is a strong Mobile penetration and communication system developed to help reservation through mobile, automatic return communication of confirmation of reservation, Internet facility for large many features etc. But somehow ticket window queue is still an issue with Indian Railways.

Asset Utilization

Improving asset utilization of rolling stock in particular is having direct impact towards revenue generation. Asset utilistion is in terms of higher availability of asset for revenue earning and its reliable working with reduced detention. Improvement in signalling system, locomotive and rolling stock(wagon and coaches) resulted more trains per Km of track and increase in load per train. This has helped in improving financial health of the Railways. The table below demonstrates the capacity utilisation of track increasing 167% and average train load per train by 44% in 2011-12 as compared to 1980-81.

|

Year |

NTKM/RKM |

PKM/RKM |

GTKM/RKM |

Average Train Load in Tonnes/Train |

|

1980-81 |

4.34 |

5.15 |

12.55 |

1721 |

|

1990-91 |

6.30 |

7.12 |

18.13 |

2122 |

|

2000-01 |

6.96 |

9.49 |

21.95 |

2533 |

|

2008-09 |

10.43 |

15.53 |

29.29 |

2962 |

|

2009-10 |

11.7 |

16.35 |

30.82 |

3042 |

|

2010-11 |

11.35 |

17.36 |

31.88 |

3063 |

|

2011-12 |

11.94 |

18.30 |

33.50(+167%) |

3086(+44%) |

This has taken into consideration the work input in doubling/tripling of track also. It may be a subject of debate whether Indian railways has optimised the potential of track utilisation. If one takes the track capacity utilisation of Mumbai suburban network as benchmark, then certainly there is adequate scope to work on that.

Indian Railways has also gone for incremental adding to the carrying capacity of the wagon by +2 tonnes in different phases and now reaching to the level of CC+6 and CC+8. Initially a freight coal/iron ore load train consists of 48 BOXN wagon which has now been increased to 49, but it is not possible further due to limitation of loop line. www.indianrailways.gov.in/railwayboard/uploads/directorate/traffic_comm/Freight-Rate-2K11/RC_28_11.PDF

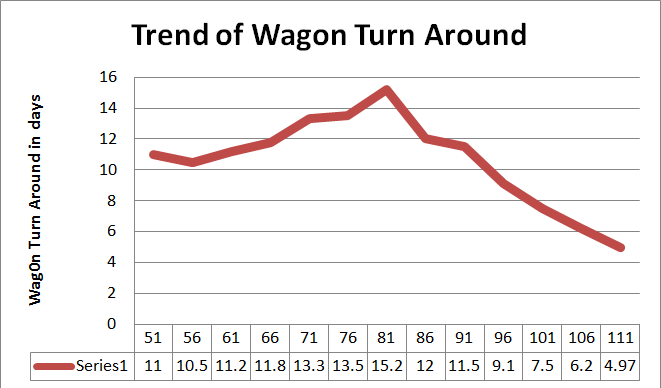

Wagon turn around is the other important indices which has resulted three times better loading potential of a wagon since 1981 from 15.2 days to 4.98 days. A wagon loading capacity improved 24 times per year to 73 times a year. This improvement has come consistantly on a regular basis but it is stated that this has been pursued more vigorously during Gujral, Madhav Rao Scindia and Lalu period. Look at the trend of wagon turn around improvement.

In order to address line capacity constraint, Indian Railways is presently making effort of heavy haul by amalgamating two trains when long distance running path is feasible.

High Horse Power Locomotive

Indian Railways upgraded existing class of locomotive and decided to import latest technologies from experts in the field. Tractive effort helps in start and acceleration of load whereas it is the horse power which gives speed. The advancements has come through up gradation of existing class of locomotive and import of new technologies. A balance between the two has helped IR in improving average train load . One may question lost opportunity due to delays High Horse Power factory at Madhepura and Maruraha but it is the continuous efforts of RDSO and PU which led to this development.

ü Up-gradation of Existing class of locomotive

- During 80’s maximum of 3600HP WAM4 locomotive was existing over Indian Railways. Indigenous efforts made successfully to increase it to 3900 (WAG5) and thereafter to 5000 HP WAG7 for freight hauling freight train. This was done by borrowing bogie technology of WAG6C class of locomotive. It could be possible to replace a need of two locos for hauling 5000T train on 1/200 gradient section. Similarly with 5000 HP WAP4, it could be possible to haul 24/26 coach passenger train at 110 Kmph.

- Similarly during 80’s it was WDM2 2600 HP Diesel Locomotive dominating over Indian Railways and the capacity of the locomotive increased in steps with absorption of different indigenous technologies. The latest class is 3600 HP high adhesion 105 Kmph WDM-3F locomotive.

ü Import of new technology from ABB (6000 HP WAG7 and 5000 HP WAP5) for Electric and GM (4000 HP WDP4 and 4000 HP WDG4 for Diesel. Efforts are in progress to upgrade these locomotive with possible technologies to 6000 HP WAP7 , 4500 WDP4B, 5500 WDG5 class. More details of Diesel locomotive at http://www.irfca.org/faq/faq-loco2d.html

|

Year |

GTKM/Kg of tractive effort |

Average Train Load in Tonnes/Train |

|

1980-81 |

2372 |

1721 |

|

1990-91 |

3873 |

2122 |

|

2000-01 |

4498 |

2533 |

|

2008-09 |

5158 |

2962 |

|

2009-10 |

5326 |

3042 |

|

2010-11 |

5286 |

3063 |

|

2011-12 |

5184 |

3086 |

Introduction of Second and Third AC and Double Decker Air Conditioned Coaches

Development of AC 2 tier started around 1977 and that of AC 3 tier in 1988 and were the most successful development in passenger coaches. It has not only helped Indian Railways to generate enough of revenue but also met the demand of middle class for comfortable train journey.

The passenger carrying capacity of a train is limited by length of the platform. Indian Railway took the decision of extending the platform to accommodate 24/26 coaches of which 24 are passenger carrying coaches and balance as spare capacity of parcel/inspection Carriage etc. This has put a limitation on the carrying capacity. Now the next possibility is to look into the total envelope permitted depending schedule of dimensions and if we can accommodate more passengers. This led to the development of design for Double Decker trains. Double Decker trains were initially introduced between Mumbai-Surat which was non-airconditioned and invited many complaints of heavy dust for the lower compartment.

As stated in vision 2020 document, an air-conditioned double Decker was considered an alternative to enhance passenger capacity over inter-city route. As on date double Decker trains are plying over 7 heavy passenger routes.

The most important point to note here is the complete indigenous development of these class of coaches.

LHB coaches were introduced over Indian Railways with import of technology from Germany along with transfer of technology to manufacture it in India. The coach has the potential to run at a speed of 160 Kmph with oscillation trial done at 180 Kmph but has not been used at a speed of more than 130 Kmph in service.

Three Phase Technologies in EMU

EMUs are most energy intensive mode of transport to meet the sub-urban traffic demand. This is in view of the frequent stop and start with acceleration level ranging from 0.8 to 1.0 m/sec2. This required huge consumption of electricity during acceleration and waste during braking. SEC is ranging between 40-45 kWh/1000GTKM. Introduction of three phase EMUs provided an opportunity for regenerative braking with regeneration of 35-40% energy back to system. This reduces the SEC to around 25 kWh/1000GTKM, an attractive proposition to go for three phase IGBT traction system.

Indian Railway first introduced three phase induction motor EMUs over Mumbai Sub-urban network in the year 2000 with GTO base technology from Alsthom and BHEL ( in association with Traxis of Netherland). In the meantime IGBT device got developed for traction power system and Indian Railways decided to go for this technology in the next contract finalised with M/s Siemens. The next on-going contract is M/s Bombardier, the trial of their first unit is under progress.

Beside three phase technologies, these stock are equipped with stainless steel body and interior, forced ventilation, air springs for passenger comfort.

The most important next step was creative thought to introduce 10 feet wide EMU stock fitting into maximum moving dimension for working on main line and called Mainline Electrical Multiple Unit. This has started replacing passenger train and improved their reliability, punctuality, no-nonsense alarm chain pulling, average running time and brought delight on the face of a common man. For non-electrified route, Diesel Multiple Units were introduced on the same concept and well appreciated by the passenger.

Bifurcation of Railways

Six Ex-Chairman Railway Board an open letter to the PM in the year 2002 have opined, “The creation of new zones will be an operational debacle, a financial disaster and an administrative blunder.” Indeed, the punctuality of train operation is likely to be jeopardized. Due to increase in interchange points as a sequel to the creation of new zones, speed will have to be reduced and time will be lost while crossing different interchange points. Table-2 below shows the increased number of interchange points and zones, which will act like speed-breakers.

| Route | Existing zones | Changed zones | % of increase |

| Delhi-Mumbai | 3 (NR,WR,CR) | 4 (NR,NCR WCR WR) | 33% |

| Delhi-Chennai | 4 (NR,CR,SR,SCR) | 6 (NR,NCR,WCR,CR,SCR,SR) | 50% |

| Delhi-Howrah | 2 (NR, ER) | 4 (NR,NCR,ECR,ER) | 100% |

From the administrative point of view, the creation of 7 more zones will breed bureaucratization instead of decentralizing the power to divisional headquarters. More powers need to be delegated to the field formations in the division and stations. Since the communication system in the Railway has improved to such an extent that territories in the remote corner of the country can easily be coördinated and efficiently managed, bifurcation does not stand to reason.

Out of total 63,028 route Km of Indian Railways all the 9 zonal Railways are having 5000 to 6000 route Km on an average under its jurisdiction except Northern Railway having 11,047 Km and Western Railway. 10,020 Km. So even in terms of route Km, no other zone except WR and NR needs bifurcation from the administrative angle.

So intense was the resistance against bifurcation of Indian Railways adding 7 more zones making it to total 16 zones.

All the doubts raised by the senior intelligentsia were found misplaced because no such damage observed. The most important reason for that is no Railwayman will ever dare to stop a running train when changing zones or divisions. In fact, financial damage also got absorbed and today no one Railwayman talks about it except about creation of new zone particularly at Hazipur, which is the outcome of consecutive Minister of Railways from Bihar to gain political mileage. Indian Railway ensured the bifurcation not to fall in line with State boundaries which would have led to the chorus of demand for Railways to be a State subject instead of present Central Subject.

Creation of Public Sector Undertakings under charge of Ministry of Railways

Indian Railway had only 2 PSU namely RITES (1974) and IRCON (1976) pre-1980 but created as many as 11 PSUs and taken over 3 sick units. Taking over three sick PSUs was a political compulsion. These are namely Center for Railway Information System (1986), Indian Railway Finance Corporation (1986), Container Corporation of Indian (1988), Konkan Railways Corporation of Indian Ltd (1990), Indian Railway Catering Corporation of Indian Ltd (1999), Mumbai Rail Vikas Corporation, RailTel Corporation of India Ltd (2000), Pipava Rail Corporation of India Ltd. (2001), Rail Vikas Nigam Ltd (2002), Rail Land Development Authority (2005), Dedicated Freight Corridor of India Ltd (DFCIL 2007).

It may be difficult to account contribution of the PSUs in taking Indian Railways, where it stands today, but in financial terms it has generated a net profit of Rs. 1782 Crs. There is certainly a question mark that without the creation of these PSU, was it possible for Indian Railways to produce the assets it has done during the last 30 years?

There is Parkinson’s Law proposed in 1955 by UK political analyst and historian Cyril Northcote Parkinson (1909-93) which states that “a sufficiently large bureaucracy will generate enough internal work to keep itself ‘busy’ and so justify its continued existence without commensurate output.” This is a law and shall hold good irrespective caste, creed, generation, society and country etc., and therefore, equally applicable in India. If that be the situation, Indian Railways being a Govt. entity will have limitation to reach new heights, and therefore, creating PSUs with delegation of powers different as compared to Govt. will certainly help in producing more output as compared to cost input.

Railway Electrification

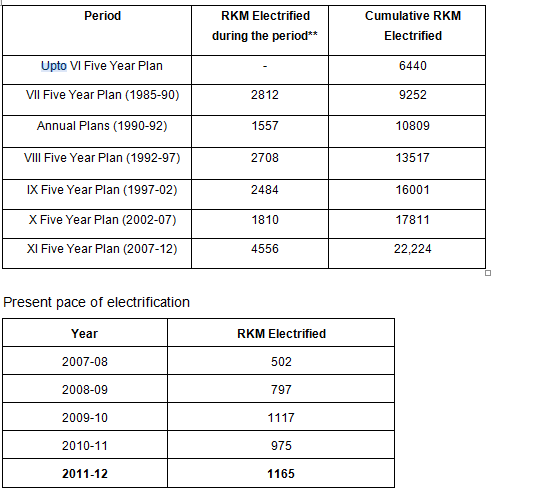

Railway electrification means provision of infra-structure to transfer electric power from fixed infra-structure to a running locomotive so that it works on electricity as against prevailing diesel fuel. Economics of diesel versus electric has always been a subject of debate, and therefore, electrification has not progress well over Indian Railways. Trend of crude oil prices in the international market and foreign exchange had decided the pace of electrification over Indian Railways. Progress of electrification is as follows:

Countries owning large oil fields have not found electrification financially viable except for urban and sub-urban transport. But the situation in India is different where 70% of the oil demand is met through import. This results Indian economy depending very much on international crude oil prices and foreign exchange. Electric power generation is predominantly thermal and hydro base and electricity unit prices as prevailing goes in favor of electric traction with long-term benefits. Indian Railway calculates haulage cost for coaching and freight on diesel and electric traction. This figure for the year 2010-11 is as follows:

| Diesel | Electric | |

| Coaching | 270 | 144 |

| Freight | 165 | 97 |

From this it can easily be seen that hauling coaching and freight train by electric is 53 and 58% as compared to diesel traction. One can imagine that had the electrification not progressed, the financial position would have been very bad.

Reforming approach to Transportation Business - Gujral period 1981-83

During 70 and 80s, there was an increase in the militant activity in India and irresponsible unionism. Thither was a countrywide railway strike in 1974 with dominance of trade wise unionism and recognized unions completely defunct. The strike was crushed with the support of the then Prime Minister Smt. Indira Gandhi. During 1980-81, Loco Running Staff Association, an unrecognized union was spearheading agitation, wildcat strikes and paralyzing the movement of trains. That was a very difficult period with movement of iron ore and coal to steel plants and thermal power plants were severely affected. Smt Indira Gandhi took a firm decision of sacking the entire board and asked Mr. Gujral to take over as Chairman, Railway Board who was working as General Manager/Western Railway at that time. He was having only seven months to go for retirement when he took over as CRB. While working in Asansol Division and in South Eastern Railway, he had close encounters with LRSA.

His first object after taking over as CRB was to guarantee supplies of raw material to steel and thermal power plant and other industry that were depending on Railways. On finding actions of the LRSA going beyond limits and calling for a strike on 16th Jan 1981, Gujral invoked 14/2, a clause in D&AR wherein an employee can be dismissed without inquiring if the situation so warrants with reasons recorded. 100 employees per Railway were removed under 14/2 within 72 hours ensuring visible impact among railwayman fraternity.

- No top leader sacked

- Class IV employee not sacked

- Employee not living in Railway colony need not be taken up as it will not make any impact.

Beside 14/2, police arrest and D&AR action under SF1 and SF5 were also initiated to break the unity and family of the staff looking at helpless leaders as villain. The strike failed miserable and all unrecognized unions crushed completely. Result was that till date, no strike and there is every doubt that any Union will ever attempt. With this Mr. Gujral dictated his authority over the system.

He identified short term and long term measures with implementation plan as follows:

Short Term Measures

- Segregate roller-bearing from plan bearing stock. Plain bearing stock was unreliable with frequent case of failure. The fundamental was simple to keep all reliable stock in one train formation and achieve reliability of train running. Run plain bearing stock for short-distance trains

- Segregate CBC and screw coupling stock. There were frequent breakage of screw coupling and this decision has helped in ensuring at least few reliable train formation

- Crack running of trains in which a crew runs his train bypassing one crew changing station. For this he was given bonus.

- Ensure that trains formed at starting station are attended fully without requiring any attention en-route. Front covers of the roller bearing of such trains were painted with yellow color for easy identification by maintenance staff.

- To replace steam locomotive by diesel and electric locomotive. So was the intensity of this order that electrification of unwired lines at Dongaposi, Adityapur, Bondamuda and Tata Nagar Yard of Chakradharpur Yard were done in record time with internal resources. I was working at Chakradharpur Division of Indian Railways at that time.

- Electric ad Diesel locomotives were the costliest asset at that time and he introduced the concept of real-time monitoring of its utilisation.

- Stopped piecemeal booking and shifting priority of transport for train loads only. This results closure of good sheds and humping yards. This has a downfall as IR lost wagon load traffic to road.

- Permitting overloading to the extent of 2 tonnes per wagon over the carrying capacity.

Long Term Measures

- To introduce air brake wagons

- To scrap all steam locomotives and introduced Diesel and Electric Locomotive instead. This was an important decision to improve efficiency.

This was the period in which the concept of performance and results oriented culture was developed. This was further taken up when Madhav Rao Scindia was Minister for State Railways in 1986-89. He is accredited with the modernization and computerisation of Indian Railways with maintaining the most cordial and professional relationship with his managerial cadres. He was the first MOSR who questioned the availability and reliability of fixed and rolling infrastructure. Questioning alone from the big boss motivates the organisation to improve its functioning.

So was the impact of this period over Indian Railways. He was given extension for this contribution and retired on 6th Feb 1983 after serving for a period of 27 months.

Turn around Story of Indian Railways - Lalu-Sudhir period 2005-09

You may also like:

- Where has 150 millions Indian Railway passenger gone?

- ‘Rescue’ Indian Railway passenger business through statistical indices ‘RSKU’

- Why no steps to digitize issue of free travel pass…

- Average speed of freight train over Indian Railways

- Mechanized measurement and inspection – a help to cut down…

- Why IR passenger traffic heading south?

excellent.

I have fun with, result in I found exactly what I used to be looking for.

You have ended my four day lengthy hunt! God Bless you man. Have

a nice day. Bye