Power Supply System of Indian Railway Coaches

Indian Railways have 46,038 various types of coaches (excluding EMUs and MEMU coaches) and around 3000 of new coaches are being added annually to the system. There are two classes of the coaches called conventional and LHB being manufactured at ICF/Perambur and RCF/Kapurthala respectively.

There are three power supply systems as existing over Indian Railways to provide illumination, fan, air-conditioning and other miscellaneous needs of electricity for travelling passengers. These are

Self Generating (SG)

2×25 kW alternators for AC coach and 1×4.5 kW for non-AC coach is mounted underslung, driven by a pulley-belt arrangement when driving pulley is mounted on coach axle. Output is rectified and charges 110V DC battery for continuous power supply to AC and non-AC coaches. AC load of roof mounted packaged units is supplied by converting DC into 2×25 kVA inverters. This system is followed over trains having a combination of AC and non-AC coaches.

End-on-Generation (EOG)

Two power cars each equipped with 2×750 kVA DG sets, one at each end of the train, supplies 3 phase power at 750 V AC power to each electrically interconnected air conditioned coach. The voltage is stepped down to 3 phase 400 V and supplied to standard voltage equipment on each coach. EOG system is followed for fully air conditioned train like Rajdhani, Shatabdi, Duranto, Garib Rath, Premium special trains. Import of LHB class of coaches from Germany is provided with the EOG system with a promise to provide SG system design for indigenous manufacturing. SG technology given was a complete failure and IR is still struggling to develop designs for the last 15 years.

Head-on-Generation (HOG)

Power is supplied from the train locomotive at the head of the train. The single phase 25 kV transformer of the electric locomotive is provided with hotel load winding which is converted to three phase AC at 750 V using 2×500 kVA inverter and supplied to the same system as that of EOG. In case of Diesel Locomotive, three phase alternator is mounted on the traction alternator and feeds the hotel load. This is the most efficient system as the cost of power is about 25% less as compared to EOG, but the system is still under development for the last 30 years. The other class of trains namely Electrical Multiple Unit and Main Line Electrical Multiple Units employs the same system for coach lighting. The system is similar to what is followed in train-set composition of train having a power unit at head as well as on tail and power the entire load of the coach for comfort.

Running of mixed LHB design AC and non-AC coach

There is a need for running a mix of AC and non-AC coaches with LHB coach design to improve passenger satisfactory, higher capacity and improved riding with less maintenance. RCF has already started manufacturing Non-AC LHB and 276 such coaches have gone into service till 31st March 2014 and working on Northern Railway, North Western Railway, Western Railway, East Central Railway and Eastern Railway. The only way to power these coaches is by EOG system as the SG design not yet successful. The electrical load of the train is about 250 kW and with a diversity factory of 80%, system loading will be around 200 kW for which the existing power cars is of over capacity.

Development history of SG AC LHB coach

For manufacturing of Non-AC LHB version, M/s LHB provided Indian Railways a design for driving the alternator with cardon shaft arrangement as per the terms and condition of the contract.

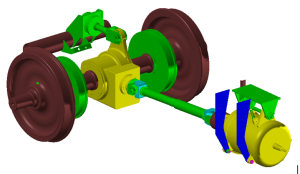

Cardon Shaft Arrangement

In this arrangement, 25KW alternator was of conventional type except belt transmission replaced with a cardon shaft which was driven by a gear box mounted on the axle. The alternator was mounted on the coach underframe to take care of space constraints in the bogie. This design was given by LHB to RCF as per the contractual condition. Based on this design, one rake was turned out to work in Shalimar rake (4545/4646). The rake turned out by RCF worked between NDLS & JAT for few days but design lapses surfaced out within a short period. The design lapse was non-damping of vibrations emerging from the track irregularities resulting failure on account of breakage of gear box & Cardon shaft, failures of fasteners provided for coupling of Cardon & gear box, shearing of flange for coupling, jamming of Cardon shaft arrangement, development of gap between torque limiter plates, breakage of gear box torque arm pin cap locking stud in Cardon shaft system and damage of fork arm bolt provided in Cardon shaft arrangement.

The rake turned out by RCF worked between NDLS & JAT for few days but design lapses surfaced out within a short period. The design lapse was non-damping of vibrations emerging from the track irregularities resulting failure on account of breakage of gear box & Cardon shaft, failures of fasteners provided for coupling of Cardon & gear box, shearing of flange for coupling, jamming of Cardon shaft arrangement, development of gap between torque limiter plates, breakage of gear box torque arm pin cap locking stud in Cardon shaft system and damage of fork arm bolt provided in Cardon shaft arrangement.

Failure Mode of Cardon Shaft arrangement

Alternator mounted directly on Mid Axle

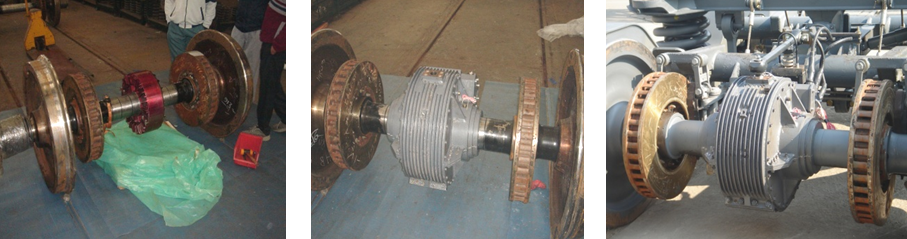

RCF took initiative of developing of Permanent Magnet Alternator fitting the rotor directly on the axle of the wheel itself. The rotor consists of a solid core with embedded permanent magnets with no field windings. The stator is in two halves and provided on the axle with the help of split bearings on both sides of the alternator. The stator is held in position with a reaction rod, which is secured with the stator on one end and bogie on the other end. There is no belt drive in this system.

Constructional details of mid axle PM alternator

These type of alternators were developed by M/s Landert HMTD, Mumbai and 4 nos. of alternators with ERRUs were commissioned successfully on LHB SG ACCN coach nos. 05143 & 05146 and put on 06 to 08 months commercial trial in Shalimar Rake (4545/4646) ex. NDLS to JAT and with a lot of problems when put into service. Finally, the coaches were detached from the Shalimar Rake and sent back to RCF by Northern Railway. The defects observed were damage of bearings, grease leakage, damage/burning of stator windings & insulating material, breakage of terminal box, accumulation of copper dust and repeated control card failures in ERRU etc. Apart from above, M/s. Landert, Switzerland, who was the technical partner of M/s. HMTD, Mumbai did not technically supported M/s. HMTD. The most important issue of the design was that if the bearing fails, it results in immobilization of the coach, most severe condition of service failure and project failed.

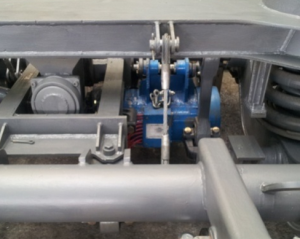

Belt Driven Permanent Magnet Alternator

The existing Alternator used in conventional SG AC coaches cannot be fitted in the LHB-FIAT bogies due to space constraint in FIAT bogies. At this stage, Indian Railway was in look out for a smaller size alternator which can be fitted within the space available. It was well-known that the size reduces considerably with the use of a permanent magnet alternator and that gave the lead. Two numbers of belt driven 30 kW alternators with permanent magnet were developed and installed on a coach for trial. This design has been developed in close coördination of RCF, RDSO and M/s I.C.Electricals. This coach has been running in regular service since Nov. 2012 with satisfactory performance. The advantage with permanent magnet is due to reduction in the size of the rotor as it does not have winding to generate electric field, and therefore, a reduction in overall size, weight, efficiency, durability and you name the advantage, it is there. But the progress is slow for two reasons

- Only one source so far and unless there is a competition, the firm will jack up the price. Two more sources, namely HMTD and Signotron has been given dimensional fitment clearance by RDSO.

- Jacking up the price of permanent magnet in the international market by China finding the demand going up for its useful application in motors and alternators. Developers already finding difficulty in supplying the permanent magnet alternator at a reasonable cost.

- Permanent magnet alternator is going to be a major source of providing magnetic field in traction motor with the intention of reducing size and application in low floor height driving coach in metro rakes.

Financial Viability of different systems of power supply

- HOG system is considered to be the most economical for the reason the cost of generation is minimum, but the issue is that the head on locomotive is not wedded to the train. If for some reason, it is detached, there is no source of power, therefore, one power car has to remain in the system. There is one more angle to this, that if the power car become mechanically sick en route and detached then continuation of both the power cars justified even with HOG. This is the reason that there is not much enthusiasm for HOG.

- There is always debate about the economics of SG versus EOG and each group justifying in his own way. EOG favours all factors over SG, except two i.e. the earning capacity of the power car and loosing flexibility of interchangeability . For this, the initiative was taken to develop under slung mounted DG set, thus releasing the space for luggage. If this is done, all economics will shift towards to EOG system. As regards, flexibility of interchangeability, successful running of LHB coach train mix with AC and Non-AC on EOG has proved this wrong and is only a fear.

- The most important financial, practical and workable solution is to develop under slung mounted DG sets in two versions of 2×750 kW and 2×250 kW for fully AC and mix train of AC and non-AC coach . This will release 50% of the space presently used in the power car for DG set and power panels. The design of the power panel shall be so chosen to have the flexibility to draw power from HOG as well. The cost of electric energy through HOG will be much less as compared to EOG.

RDSO initiated the development process about 10 years ago, but not yet successful. This one development alone can change the complete scenario of power supply system benefitting Indian Railways in the following respect.

Energy Efficiency: The energy efficiency of SG system is very poor if the efficiency of the entire system of mechanical power generation at the train head to conversion into electrical is taken into account and works out to be around 50% as compared to 80% of EOG.

Capital and Maintenance Cost: The capital and maintenance cost of a large number of under slung mounted equipment such as alternator, pulley, belt, Electronic regulator, battery and invertor will get a go bye with the addition of maintenance cost of four numbers of DG sets and their panel. It is the total quantity of these items in SG coaches that makes the difference in all aspects of reliability and maintainability.

Indian Railway shall take up the project of development of under slung mounted DG sets power cars for EOG power supply system to help energy conservation, cost reduction, durability and maintainability.

You may also like:

- Why Faraday’s research is revolutionary to start the era of…

- How Resistance is important in understanding Electricity?

- Why IR passenger traffic heading south?

- Average speed of freight train over Indian Railways

- Where to begin to understand Electrical Engineering?

- Indian Railway Context – Sanding to improve adhesion

Sr, lm tryng to contactall in govt.n railways to explain my idea of CLLEAN N FREE ENERGY to-1.make railways totaly free of its runing cost (34000cr.per annum) 2.railways save 20 to 25%on its station power bill 3.save country 10to 15% on its total energy needs – All with FREE clean energy n it is all replacement energy being used here can be used else where if any one cn help

Yes, I will certainly help if you share your idea and how it can help railways saving running cost of rs.34000/-. There may be some wrong assumption, resulting in some biased result. I can assure you that your idea remains your propriety item but my help will only be if I am sure of the basics.

sir can i have your email address i wanted to forward my proposal for energy saving

POWER PRODUCTION THROUGH RAIL TRACK.

RUNNING TRAIN & POWER GENERATION

Production of electricity, by most economical means, which is 100% echo-friendly, without the use of any raw materials, according to requirement.

This project which was developed by Mr. Antony Louis of Vaduthala in Cochin after years of hard work and observations and study, is registered for patent, both Indian and International, and has since been published, can be used for various activities.

Project I

By attaching a unit, with an alternator mounted on a specially designed chassis to the rear of a train in service, power produced can be supplied to the sub-station on the routes. The train can be made to move on the system currently in use and the power produced by the alternator attached (as in the case of a dynamo fitted on a cycle) can be supplied to the fixed sub-stations through additional cables and supplied wherever it is required.

Project II

Train engine on a round shaped track. We attach a chassis as per design and mount an alternator, with the capacity as required. Power is produced when the engine moves. Power for the engine can be given from the 25000 Volt power line according to the distance covered and the load it has to carry.

According to the report from the Southern Railway, to carry 1000Tons for a distance of 1 Kilometer the engine requires 6.45 KWh.

If we consider number of chassis/alternators that can be carried in accordance with 1000 Tons, the magnitude of the power production can be ascertained.

A report from PCT Alexandra says: Novelty, Industrial Applicability

The project when put into use, power production and industry becomes profitable, and is echo friendly and pollution free.

Project III

This project can save 70% -90% of power for the trains in operation. If a unit with a 25KV alternator is attached to the rear of a train, the train’s moves on power from the sub-station. Just as buildings use power from inverter, in case of power failure, at the maximum speed of the train engine and at the rpm of the alternator, the power produced can be used until the train stops.

In foreign countries they use engine which store power before start. If such engines are used, the power produced by the alternator can be used to run the engine and to store for further use or for startup.

Antony Louis

For FURTHER DETAILS & FOR DEMO PRESENTATIONS CONTACT W.Z.PETER

0091-9446001285

Your suggestion technically not possible. You failed to understand that what ever you generate (what ever you call it a innovation), the power is spent from the engine attached at the front of the train. From your understanding, the power produced by underslung alternator in a coach produced power free. But it is not so. Don’t waste your time and energy on such thinking which is against the natural laws.

Thank you

the alternator and invertor are placed on the specially made chassis.This specially fabricated chasis run along with the train and the power is produced from this chassis and not fitted with under slung alternators.

Power produced from the alternator can be sent to substation through additional cables

What is the source of powering the alternator mounted on the specially made chassis which run along with the train? Is it air motion? If you want to generate power from this air motion, it will put additional drag on the locomotive. The train resistance is given by a+bv+cv*v, where c is the air drag coefficient. The value of c will go up and what ever is generated, will add to the train resistance. IIT student did experiment at DMRC, where the tunnel drag is very high, but could only produce of few watts where the alternator was installed at the exit of the tunnel.

we attach a specially designed chassis with additional wheels as per design and with an alternator, with the capacity as required is mounted. The additional wheel moves the specially designed gear to rotate the alternator. Hence power is produced when the engine moves.

By attaching a unit, with an alternator mounted on a specially designed chassis to the rear of a train in service, power produced can be supplied to the sub-station on the routes. The train can be made to move on the system currently in use and the power produced by the alternator attached can be supplied to the fixed sub-stations through additional cables and supplied wherever it is required

I could not find a provision to attach our designs to you for your views

He has failed to understand the basic concept of Conservation of Energy. To haul those compartments with alternators underslung, You would have to spend more energy at the Engine(Due to Lenz’s law, The alternators will resist the wheels when they produce electricity). The main loco engine will burn more fuel/electricity. And we know that designing a 100% efficient system is Impossible, Let alone making it more than 100% efficient. Stay in school, Learn physics boy!

Indian govt has launched a plate form as Innovation Challenge of Indian Railways where you can directly send your innovation for further approval Last Date- May 21,2017 visit mygov and register your entry.

This idea does not follow law of conservation of energy. No machine can produce more energy than the source. There will be a loss obviously.

The idea is good but its not work in trains . It can be work some mini vehicles

very descriptive pictures

Hello Sir, we have an idea of developing an automatic lifting system which helps disabled persons to board the train without the help of others.Is there any provision for implementing this system in Indian Railways.If it is so, to whom we can approach with our idea.

I want to know that which power are available in Indian Railway coach, and how many voltage are available to operate light & fan.

The light and fans are operated at 110V DC or AC to ensure safety of passenger. There are three types of power supply arrangement i.e. SG-Self Generating-110 V DC by an alternator driven by the coach wheel, EOG-End-on generation in which the end coach is mounted with DG set and transfer power to the train through coupler. In EOG system, in order to avoid voltage drop, the voltage is raised to 750 V and than again converted back to 415V. The recently developed system is Head on generation where the power is taken directly from the locomotive and transferred to the coach in the similar way as that in the EOG sytem.

I wish to put-up for your kind consideration an Idea which can help IR save over Rs.1000 crores, conserve over a billion KWh of electricity and prevent emission of over a million Tonnes of Carbon Dioxide into our environment every year.

As narrated in the enclosed Brief and explained with diagrams, the Idea is pretty simple and easy and quick to implement. It calls for a very little investment and payback period is less than two years. Moreover, the concepts encompassed in the Idea are time tested and standardized for trouble free performance.

The Idea has potential to go a long way in achieving the national objectives of Energy Conservation and Environment Protection and thus come handy in contributing to fulfilment of Our PM’s objectives on these counts.

In view of the above, I request your good self for an in depth evaluation of the Idea and help me in contributing whatever I can for benefit of my country and the society.

The Idea : Retrofitting of Self Generating (SG) System of Passenger Coaches – Brief

Objective : Energy Conservation and Environment Protection

The above said idea envisages modification/retrofitting of electrical circuits of the existing SG Coaches of Indian Railways so as to yield an efficient system to meet the Hotel Load or Utility Power requirement of passenger coaches in Indian Railways.

2 Here-in, characteristics of electrical power’s input and output at various components of the SG System are put to use and the modification/retrofitting, so suggested; will enable the electrical equipments of the passenger coach, otherwise operating on SG System, to operate on the single phase AC power supplied by the HOG or TPC without any additional phase converter/s (bulk or individual).

Addition of Capacitor/s or RC filter/s is envisaged to take care of higher ripple content of rectified single phase AC power.

Note :- The Traction Power Converter or TPC refers to the group of electrical equipment assembled to draw electrical power from the traction line and render it suitable for operation of utilities of the passenger train to which it is attached with/without any further electrical activity e.g. step-up/step-down, rectification/inversion etc.

3 The Idea can be applied in several ways to provide a traction power based electrical power supply system for the utilities. For example:-

3.1 Substitute the electrical power from alternator by that of HOG/TPC and this arrangement will yield a Universal Power System which will work both on electrified and non-electrified tracks (Fig 2).

3.2 Remove the alternator and connect the stepped down single phase electric power from HOG/TPC to the rectifiers (Fig 3.1). The so retrofitted arrangement termed as ‘Practical Power System’; will make the respective coach lighter with even better numbers on energy conservation and environment protection.

Though coaches with Practical Power System are suitable for electrified tracks but will permit limited operational flexibility with deployments involving short/complementing non-electrified tracks as well.

3.3 In addition to doing away with the alternator, substitute the battery with a smaller one (Fig 3.2). The resultant retrofit, termed as Optimal Power System will yield even better energy efficiency and pollution control values but such retrofitted coaches could be deployed only on electrified tracks.

4 This Idea is expected to help provide Techno-economically viable, cheaper and cleaner source of utility/hotel power to operate the utilities of passenger coaches.

The Drawings stated in the above Brief could not be attached as I failed to upload the related PDF. Please let me have the link to upload the same.

For further clarifications, please contact:- Subhash Chander

e-mail ID : subhashchander52@gmail.com or subhashchander52@hotmail,com

I appreciate the application you have put in to suggest saving measures. I would like to explain the systems existing over IR and the issues involved thereon

1. SG system is widely followed where in each coach is capable of working as one unit independent of rest of the train. An alternator is attached to the wheel and the output rectified to charge a battery at 110 V DC. This stored power is utilized directly to light and fans in sleeper coaches and through a three phase inverter to AC coaches. The sytem is energy inefficient, large number of components, maintenance and theft issues.

2. EOG system is widely used in Rajdhani, Shatabadi, Duronto, Garib Rath type of trains having inter coach connectivity in which a Power car equipped with DG sets in connected at each end. There are two DG sets in each Power car with 100% redundancy. The power is stepped up to 750 V 3 phase AC and distributed to each coach where it is transferred to 415 V 3 phase AC and distributed to coach for different applications. The disadvantage is that the coach is married to the train and can only be changed with the same type of coach. It requires additional manpower for power car manning etc.

3. HOG system. IR is working for Head On generation for the last 35 years but could not be implemented due to many constraints. EMU/MEMU type trains are basically with HOG type of system. The new series of passenger locos WAP7 is equipped with additional winding for hotel load along with an inverter to supply constant frequency supply. This power is taken to the adjacent coach and transferred to the train through a change over switch. The challenge is that only one power car can be replaced and one has to be kept to supply power during failure of the locomotive or immobilisation of one of the power car. This arrangement give significant saving in diesel oil. IR is looking how to make use of part of the power capacity for carrying passengers. HOG is the future and IR is working accordingly.

You may send me the drawings on my mail maheshkumarjain@hotmail.com and will certainly examine from the view of point of the previaling technologies and the possibilities of its applicability over IR.

Dear Sir,

I had, on July 3rd, e-mailed the relevant drawings of my Innovative Idea and had submitted a narrative to explain the Idea and its benefits. Following three Annexures, one each on :-

1. Drawings of the Retrofitted Power Supply System

2. Brief of Retrofitted Power Supply System

3. Brief of Traction Power Supply System

have been annexed to help you evaluate the Idea and its relevance for IR.

Please let me know if there are some questions/doubts.

Hope to hear from you soon – Subhash Chander

Indian govt has launched a plate form as Innovation Challenge of Indian Railways where you can directly send your innovation for further approval Last Date- May 21,2017 visit mygov and register your entry.

RAILWASY WE ARE IN REQUIREMENT OF 25 NOS RRU/ERRU 4.5 KW AS PER RDSO SPECN NO /AC/0017 (REV2).

sir,this is a nice information.How power is generated in electric locomotive trains??

Whether they use SG or EOG or some other type of generation??

A train hauled by electric locomotive draws its power in India from 25 kV single phase Overhead wire and same is converted into low voltage in the range of 1500-1000 V single. There are two types of locomotive plying in India, one provided with DC Series motor and another three phase asynchronous motor. Locos provided with DC series motor are fitting with rectifier and a online tap changer whereas the other one provided with line converter and inveter to feed VVVF control of three phase motor.

Now for providing lighting and air conditioning of coaches, there are three systems prevailing

1. SG i.e Self Generating System in which a alternator is mounted underneath the coach which draws it mechanical power from the energy of the train and converts into 140 V AC, which is rectified and charges to a battery and battery supplies all the load. For air conditioning, a three phase inverter of 25 kV capacity is provided to feed roof mounted package AC unit. This system has the disadvantage of poor energy efficiency but flexibility and can be attached to any train.

2. EOG i.e. End on Generation: This system has a generator van at both end provided with two numbers of DG sets of adequate capacity to feed the entire load of the train. The need of the system is important for fully air conditioned trains due to higher requirement of load. Rajdhani, Shatabadi, Duronta, Garib Rath type of trains are all provided with this system. The sleeper coach version of LHB coach has the limitation of difficulty of mounted underslung alternator and therefore, such trains are provided with end on generation. Except the flexibility, such trains has many advantages.

3. HOG i.e Head on generation: In this system instead of providing Generator van at both ends, the power is tapped from the main transformer of the locomotive and 2 nos. of 500 kVA inverter are installed in the locomotive or generator van and power supply fed to the system. The problem with the system is that if the locomotive fails, detached, or when the train is waiting for engine to be attached the train will be dark. Hence, only one power car can be dispensed with. The Electrical Multiple Unit trains running over sub-urban network called local trains are the example where the power drawn from the OHE is used for lighting and fannage of the coach. All over world, they are shifting to train sets instead loco hauled trains. In a train set there are two-three powered coach similar to metro trains and thus reliability of ensuring power supply to coach is fully ensured.

I hope this clarifies all your point.

Dear sir i will supply for industrial v-belts for maximum discount so please give me ur required sizes i will give best qutation & tender

We are intrested in making Air Conditioning and heater systems for various types of” locomotives” only.

Please let us know that what types of Air conditioning system along with supplier is presently used and future planning of Indian Railway.

Is it possible for us to supply the system to Railways for trials with your support and guidance? Please give us proper angencies for contacts.

Roof mounted package unit is used for air conditioning of coaches and locomotive cabs. You may visit the website of PS&EMU directorate of RDSO and can go through the RMPU specification and Electric Loco directorate to have a look of the locomotive cab air conditioning specification. You may get the list of approved supplier of RMPU from this site. Beside this, you may also go through the procedure to be followed for the method to be followed for supply of the product to Railways. RDSO is entrusted with full responsibility of developing and approval of sources.

Sir,I have an idea to improve electrical power producing capacity of our train . I am working on my idea which may be helpful in increasing performance of train. If you are interested to know about my idea I can send ppt to you. But at this moment I am going to reveal my idea sorry for that .

I am unable to understand what you want from me. You want to send and again write that you don’t want to reveal the idea.

Dear Sir I have a suggestion to utilize the engine heat generated by the EOG system to generate power using a ORC system and interested to discuss on the same.

The diesel engine used in eog is same as the one used elsewhere. Have you tried this on stationary application and if successful, than you may write your suggestion to RDSO/PS&EMU directorate.

What about using wind energy for generation of electricity. CPP type propellers can be used which will be further connected to dynamo producing DC current. This can be a good idea for SG type.

You mean using the wind flow caused due to train run? This will put drag on the train and will not serve any purpose. IIT Delhi did experiment to convert electric energy from draft created due to run of metro train in tunnel, it was not successful. As per the conservation of energy principle, if you want to convert the air flow into electric, it will offer resistance in the path of the laminar flow of air and increasing train resistance. Many other felt about this and posted question. You may also examine the answer to those questions as well.

What if an aerodynamic shape of coach is selected and position propellers accordingly. We can relate it to door side radiators used in lamborghini aventador.

In high speed coach design, all efforts are made to have a laminar flow of air such as reduce gap between coaches, skirting etc. so that the air flow does not encounter obstruction other than the locomotive head. What ever arrangement is made to generate energy, it will put obstruction in the path of air flow. As per the principle of energy conservation, the energy you want to generate has to be come from some where? This comes by increasing train resistance. The self cooling arrangement of radiator with the air flow will always result in increase resistance.

Dear sir! I would like to know what is the voltage used for running fans and lights in MEMU coaches?

110 V AC

Hello! I want to know the RDSO specification of various types of DC-DC Converters used in Indian Railway. I am unable to find those in RDSO website

hello

hello sir, its siddaling currently I’m working on train roof with solar panel project, I need some information about how much power required for per coach and how many fans , lights and information displays are using in non ac coach and also how much power required for ac coach .

With LED lighting and BLDC fan, it should be around 2.5 kW. As regards AC coach, 2 nos. of 25kW alternators are provided. It will not be prudent to consider solar panel for AC coaches.

Hello sir,

What if we add one alternator with each wheel in each bogie just like the bullet train SHINKANSEN have in JAPAN.

Is it going to make any effect on the SG of IR LHB COACHES.

From where you got to know that each wheel of Shinkansen is having an alternator connected, and even if it is, for what? The SHINKANSEN is a train set wherein the overhead power is used for the lighting, air conditioning and all other miscellaneous loads like out EMU/MEMU trains. Indian railways shall completely shift to end-on-generation which later on can be converted to head on generation. Self-generation is the most inefficient arrangement and IR shall plan all new manufacturing of coaches with EOG system.

Hello. I see that you don’t update your blog

too often. I know that writing articles is time consuming and boring.

But did you know that there is a tool that allows you to create new

posts using existing content (from article directories or other blogs from your

niche)? And it does it very well. The new articles are high

quality and pass the copyscape test. You should try miftolo’s tools

Hello I.m nutendra Singh

Tundla. Dstt Friozabad

Sir, very excellent and detailed information. Thanks a lot.

Hii sir

as Im engineer I just what to know about some information

Did any power loss in electric train and I just want to how do electic train works and what is the function of wire in the top of the train

Visit this link for understanding the working of the electric locomotive. https://globalrailelectrica.com/electric-locomotive/electric-locomotive/

Hame e.og ke bare me jankariya chahiye

EOG is called end on generation wherein a power car is attached in the front and rear of the train to feed the power supply for lighting, fans and air conditioning. More of the information is available on the blog. In case you have a specific question, please post.

Sir hame e.o.g ke bare me jankariya dijiye

rail ka dabba me electi wiring contracter name office place

S6 48 electric swichpluk no suply

Train no 15063