Braking Effort

Braking effort is the effort required to stop the train within safe braking distance. It has safety consequences. Braking effort is required to counter the kinetic energy of train running at a speed V and can be expressed as .

-

where D is braking distance, Tr(avg) is average train resistance and Tb is braking effort.

- Braking effort shall be such that it should be able to stop the fully loaded train on a prevailing ruling gradient section within Emergency braking distance governed by the signaling system prevailing on the territory. This governs the requirement of maximum braking effort.

Braking Effort is provided by means of

- Mechanical brakes: In this system, the brake shoe binds with the tread of wheel, causing mechanical energy to be converted into heat energy through friction. It is the principle braking system.

- Maximum braking effort is limited by adhesive weight for slide not to occur. Tbmax = μ*W for skidding not to occur. Braking effort shall not exceed 750KN distributed over all axles for a train of 5000T when adhesion is at 0.15. This gives the retardation of 0.15 m/sec. The time taken and distance travelled by the train if running at 50kmph or 13.8m/sec is

;

(Note: This excludes train resistance or any other resistance arising due to territory)

- Empty freight trains are more prone to wheel skidding because of less axle load. In view of this brakes are adjusted to empty condition for reduced brake pressure.

- Electric Brakes: Mechanical energy is converted to electrical energy by using the traction motor as a generator and either fed back this energy to OHE system (Regenerative Braking) or wasting across the resistor (Dynamic or Rheostat Braking). This provides smooth braking, saving on wear of brake blocks. and regeneration in specific class of locomotive.

- Regeneration is not possible in Diesel Locomotive, but partly possible to use regenerated energy for head-on-generation or for auxiliary load of the locomotive itself.

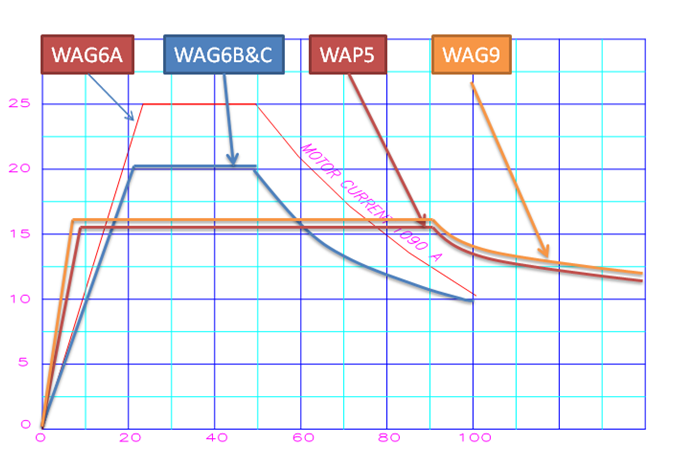

- Regenerative and rheostat braking of different class of locomotive is shown below

Maximum electrical braking effort is limited by the weight of the locomotive multiplied with a coefficient of adhesion. Considering the widely varying conditions of adhesion, the braking effort is restricted to 25T only for 6 axle locomotive.

Good description for understanding

There are many empirical formulas to calculate braking distances due to lack of understanding the theory of wheel braking. Actually, I have found that wheel braking theory has not been fully understood by the industry and academia even though wheel braking has been used for about 1,000 years.

You know braking power is applied from zero to the full power. So there are a transient state and a steady state in wheel braking. We know that the braking deceleration in state state is easy to determine , say it is A. Then the deceleration in the transient state mus t be (1/2)A. (Nobody can determine this number except me) . Not trying to belittle you calculations, if you can determine this number, then I have to say you know the theory of wheel braking. Thank you.