Understanding Maintenance of Fasteners

Threaded fasteners are widely used for joining two or more components by form fit or friction fit. Designing a fastener is very important and requires

- Selection of fastener: Selection involves size, standards, material and property class

- Positioning of fastener: Locating a fastener, accessibility, tensile/shear/compressibility forces, spring rate of joint etc.

- Determination of tightening torque: Tightening torque produces pre-load force that clamps the components and creating frictional connection between two mating surfaces.

- Pre-load force to be high enough to prevent any relative motion due to static and dynamic forces acting on it. All forces that occur give rise to possibility of deformation of components if it is more than the pre-load.

- It should not be supported by the shaft of the bolt/screw

- Pre-load force to be limited to 75% of the yield stress of the threaded fastener

- Care should be taken while calculation of pre-load when using elastic element between mating surfaces such as rubber or cork gasket.

- Vibration may cause loosening of components when it results in relative motion perpendicular to the axis of the fastener.

Mechanics of threaded fastening

It is important to understand the mechanics of what happens when tightening of threaded fastener starts. The process involves input torque, angle of turn, friction in the under-head and threaded contact and tension. There are four zones of identifiable action taking place on the fastener namely run down, alignment, elastic clamping and post yield.

- First Zone: It is rundown before the fastener head or nut contacts the bearing surface

- Second Zone: It is the alignment or snugging zone wherein the fastener and joint mating surfaces aligns to achieve snug condition i.e in comfortable condition. It should be noted that alignment is non-linear if it involves bending of fastener, non-parallelism of bearing surfaces and shall be identified at the time fastening. The contact stress at the bearing surface induces deformations of plating and coatings as well as local surface roughness and thread deformities A closed inspection of used/released fastener will identify whether non-linearity was involved during snugging action.

- Third Zone: It is the elastic clamping range wherein the slope of the torque angle curve is almost constant. This slope is projected backward to locate the elastic origin. Angle of turn from the elastic origin is multiplied by the angle-tension coefficient

to calculate the tension induced in the fastener. The elastic elongation of the bolt and compression of the parts is occurring in linear fashion from the projected elastic origin.

- Fourth Zone: It is called yield zone where the joints starts yielding and angle of turn does not produce reasonable tension or reduces the tension. It should not be mistook with stress-strain diagram of material science. This is because of yielding in the joint or gasket or threads. This is also a result of under-head embedment/thread strip etc. Once the thread strips or embedment starts, the clamping load no longer increases at the same rate relative to angular turn and infact clamp load does not increase at all, although the torque increases 20-25%.

- The clamp load at the bolt yield torque is primarily a function of the material properties of the bolt and the thread friction coefficient.

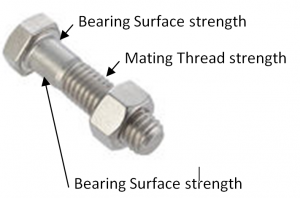

- Under-head embedment from compressed yield in the bearing area depends on the strength of the bolt or nut relative to the clamped surface strength.

- Thread strip is a function of the length of the thread engagement and relative strength of the bolt and mating thread material

The bolted joint design must completely meet axial, eccentric and side shear loads subjected on the assembly during service. This is achieved by friction and clamping force. Friction is provided by under-head and threads whereas clamping force is bolt strength. The torque applied to fastener is absorbed by under-head and threaded friction to the extent of 50 and 40% respectively and balance 10% goes into the elongation of the bolt.

Property class of steel bolts, screws etc is given as U.Y where U*100 gives ultimate strength and Y*U*10 indicates Yield Strength in MPa. The corresponding code for nut is single digit and gives the proof load stress as X*100 in MPa. The standardization of property class is 4.6, 6.6, 8.8, 10.9,12.9 and 14.9 etc. and equivalent property class of nut is 4,6,8,10, 12 and 14.

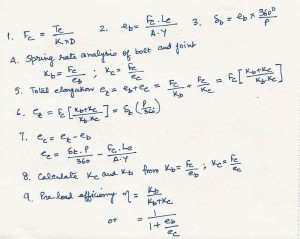

Mathematical Modelling of Bolt Tension and Joint Efficiency

Tension induced in a Bolt is directly proportional to the turning torque and bolt diameter. The proportionality constant K is called nut factor and its valued varies from 0.18 to 0.50. Let Bolt dia is D, effective joint length Le, Cross-section Area A, Modulus of Elasticity Y, Bolt Elongation, joint compression and total change are eb , ec and et , angle of turn for bolt, joint and total are δb , δc and δt , Pitch P, Spring rate of bolt and joint as Kb and Kc,

When a bolt is tightened, the elongation of bolt and compression of joint takes place simultaneously. A demonstrative graph of Tension vs total elongation showing bolt elongation and joint compression explains the concept of pre-load efficiency.

Role of Friction in tightening mechanism

When a bolt is tightened by application of torque, the same is absorbed to overcome thread and under-head friction which provides reactionary support for bolt to elongate and provide clamping force. When friction is lower due to any reason, the yield point is attained much earlier from where further rotation of bolt does not produce any more tension. The graph below explains the locus of yield point for different friction. The friction in the fastener is either natural and produced through lock nut, serrated under-head, spring washer, thread locking adhesive. With this, more tension or elongation can be induced in the fastener to take care of higher level of vibration or external forces.

What happens when thread strips?

It is very important that during tightening of a bolt, the thread shall not strip. If it strips, this limit the application of torque to produce tension. The clamping force will thus be limited at the point where thread starts stripping. Stripping of thread results embedment or erosion of thread material or under-head, which further reduces the total friction. Therefore, ever care shall be taken to avoid stripping of threads at any stage during tightening. The diagram below explains the phenomenon which is self explanatory.

Role of nut in tightening mechanism

- It should be understood that the first six engaged threads takes the entire load. In fact 1st thread takes one third, first three thread takes the three fourth and first six threads takes the full load.

- Nuts are having therefore, maximum five to eight threads

- Nuts are stronger that bolt for the simple reason that it does not have change of cross-section.

- Two threads of the bolt shall be exposed above the nut as first two threads of the bolt are poor formed.

Locking Arrangements

Role of locking arrangement is important considering the factor of reliability, safety, maintainability and cost. There are two main principle of locking arrangement namely friction and positive locking.

Positive Locking: Castle nut, Wire locking, Tab Washer, locking plate etc.

Friction Locking: Locking Nut/Jam Nut, Nylock, Spring washer, shakeproof washer and engineered adhesives.

The purpose of these devices is to increase friction that helps in application of more torque/tension thus building more clamp load. Tightening technique shall be explained to the artisan staff while using locking nut where jam nut is fixed first thereafter the main nut.

Importance of examination of fastener during maintenance

Large number of failures are attributed to failure of fasteners and there may be hundreds of reason for that. But large number are caused due to design lapses, frequent re-use of fastener, inadequate clamping force contribute significantly. Design lapses will show off during maintenance and it is the responsibility of maintenance engineer to record the of fasteners during service. He should identify

- The fasteners which are having frequent tendency of loosening

- General tendency is to tighten the loosened bolt and not to identify reasons for loosening

- Reuse of deformed/damaged/worn out bolt during last maintenance

- Deformation of mating surface and not providing frictional fit

- The fasteners which are having tendency of deformation due to subjection of lateral impact forces causing deformation

- Check for any shear stress the bolt is subject to. And if it so, the same shall be arrested first or controlled

- The fasteners which are to be tightened with torque wrench to ensure correct tightness. There are fasteners which are provided with elastic element in between and yield point sets in at much lower value of tension. The design of fastener shall take care of this aspect. It is better to advise the maintenance staff to use torque wrench for controlled tightening torque.

- This factor contributes large number of failures in which gasket deformed/damaged and pre-load diminishes. This results in cascading effect towards loosening

- The fasteners which are frequently opened due to schedule overhaul or unscheduled repairs

- A tightened and intact bolt is having a long life but will be affected depending upon the frequency of opening and re-assembly of the components.

- The fasteners which are used on assembly working in open and designer has not used coated/steel fastener

- The fasteners subjected to continuous vibration and fatigue failure of fasteners.

- Hanging items are subjected to continuous vibration

- Reuse of deformed/damaged/worn out bolt

- Deformation of surfaces under fastening

A simple corrective action will help in saving failures.

How to estimate the life of a fastener?

Life of a fastener can be estimated based on the

- Level of vibration it handles

- No. of times opened and reused or undergoing re-tightening process

- Lateral forces causing bending of the fastener or damage to the

- By examing the condition of fastener when removed during overhaul

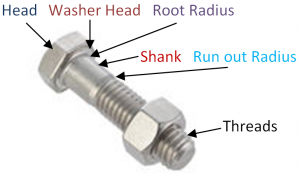

Understanding Body parts of a bolt

Washer head improves contact area. Root radius is necessary to avoid concentration of stress if it is a sharp corner. Shank provides strength to the fastner during elongation when tightened. There should not be excessive gap between the hold and shank but be clearance fit. Run out radius is necessary to avoid concentration of stress at the start of the first thread.

You may also like:

- Statistical Tools for Maintenance Engineering

- Standards method of Symbol for Units of Measurement

- CLEANING – first step to maintenance

- Condition based maintenance with M2M Bigdata Analytics

- Condition Based Maintenance – a cost effective approach

- A way forward to improve designs for sustainability of a…

It was nice to read your article. Thanks for sharing valuable information.