Standardization for Maintenance Engineering

It is due to standardization of the system in Railways that train operates over the length and breadth of the country with safety, security and punctuality. It is the language of similarity and uniformity

Define Standardization

“Formulation, publication, and implementation of guidelines and rules, specification for common and repeated use, the optimum degree of order or uniformity in a given context, discipline or field.”

The process by which Railways achieves the closest practicable cooperation among the user and stack-holders for the most efficient, economical, punctual, safe, and secure train operation

It provides

- Common and compatible operational, administrative, and logistic procedures; (e.g. Schedule of Dimension, General Rules, Subsidiary Rules, Station Working Rules. Train Time Table and Numbering System, station name, Manuals, Signage etc.)

- Common and compatible technical procedures and criteria; ( e.g. AC Traction Manual, Operations and Maintenance Manual, Trouble Shooting Directory)

- Common, compatible and interchangeable supplies, components, equipment; (Technical Specification, Schedule of Technical Requirements)

- Common and compatible working procedure at field level where many a worker works with similar uniformity

- Common symbols and unit of measurements

History of standardization

The standards became highly important during the Industrial Revolution with the need to make interchangeable parts.

Some important historical standards include:

- Sizes of screws, nuts bolts and other threaded fasteners were first standardized based on the work of Joseph Witworth

- Railroad track gauze

- Pipe sizes

- Shoe size standardization

- The screw base size and thread dimensions of electric lamp bulbs were standardized by Thomas Edison.

- Electrical voltage and frequency

- Electrical wiring and device standards

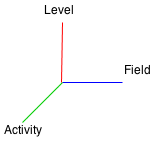

Dimensions of standardization

There are three dimensions of standardization namely

Field : Management, Train Operation, Spare Parts, Railway Equipment,

Schedule of Dimensions, Passenger Amenities,

Level: Station, Division, Zone, Indian Railways, RDSO, IRCA, Maintenance Shed,

Manufacturing Unit

Activity: Symbols, Units of Measurement, Codes of Practice, Interchangeability,

Technical Specification, Principle of Working, Dimensions, Language, Maintenance Tools,

Input-output Performance,

Standards commonly followed by Indian Railways

- International Organization of Standards (ISO)

- Union of International Railways (UIC)

- International Electro-technical Commission (IEC)

- Bureau of Indian standards (BIS)

- Research, Design and Standards Organization (RDSO)

ISO

The organization today known as ISO began in 1926 as the International Federation of the National Standardizing Associations (ISA), whose focus was mainly mechanical engineering. The International Organization for Standardization widely known as ISO founded on February 23, 1947. The organization adopted ISO, based on the Greek word isos (meaning equal), as the universal short form of its name. BIS (Bureau of Indian Standards) is the founder member of ISO

ISO International Standards ensure that

- Products and services are safe, reliable and of good quality.

- For business, they are strategic tools that reduce costs by minimizing waste and errors and increasing productivity.

- They help companies to access new markets,

- Level the playing field for developing countries

- and facilitate free and fair global trade.

UIC

The idea of creating an international organization, bringing together the railway companies, was developed in the wake of the international conference of Portorosa, in Italy on 23 November 1921, followed by the international conference of Geneva on 3 May 1922. State representatives favored the “creation of a permanent rail administration focusing on international traffic for the standardization and improvement of conditions of railway construction and operations “. The international conference founding UIC was held in Paris on 17 October 1922.Initially the UIC had 51 members from 29 countries including Japan and China, which were soon joined by the railways from the USSR, the Middle East and North Africa.

- India is a founder member of the UIC

Mission:

‘To promote rail transport at world level and meet the challenges of mobility and sustainable development’

Objectives:

- Facilitate the sharing of best practices among members (benchmarking)

- Support members in their efforts to develop new business and new areas of activities

- Propose new ways to improve technical and environmental performance

- Promote interoperability, create new world standards for railways (including common standards with other transport modes)

- Develop centers of competence (High Speed, Safety, Security, e-Business, …

IEC

- The IEC is the leading global organization that publishes consensus-based International Standards and manages conformity assessment systems for electric and electronic products, systems and services, collectively known as Electrotechnology. The IEC is a not-for-profit, non-governmental organization, founded in 1906. The IEC’s members are National Committees, and they appoint experts and delegates coming from industry, government bodies, associations and academia to participate in the technical and the conformity assessment work of the IEC.

- All international purchases of Indian Railways of Electronic and Electrical products are governed by IEC

RDSO

RDSO is the sole R&D organization of Indian Railways and functions as the technical advisor to Railway Board, Zonal Railways and Production Units and performs the following important functions:

- Development of new and improved designs.

- Development, adoption, absorption of new technology for use on Indian Railways.

- Development of standards for materials and products specially needed by Indian Railways.

- Technical investigation, statutory clearances, testing and providing consultancy services.

- Inspection of critical and safety items of rolling stock, locomotives, signalling & telecommunication equipment and track components.

- RDSO multifarious activities have also attracted attention of railway and non-railway organizations in India and abroad.

RDSO is a member of the UIC and IEC

Respect for Standards

It is difficult to imagine computerization, communication, automobile, international travel or name anything possible without seeking Standardization

Even when every effort is made to follow a standard but still the biggest problem/confusion/doubt in its compliance remains for the following reasons:

- Not knowing the standard

- Not understanding the standard correctly and implementing

- Not having a standard

- Improper documentation

- Limits of standard not defined as in the case of interchangeability

- Casual approach towards standards

- Hierarchy

- Standards not prepared in consultation with all stake-holders

Basics of standardization

Codification:

- Language of symbols, units of measurement, nomenclature etc. For every stack holder to talk and understand in one language.

- Indian railways imported Technologies from different part of the world and along with it their system of codification, units of measurement. Multiple technologies have brought the complexities of codification as well making training and de-training from one to another difficult.

Simplification and Variety Control:

- This is the most important factor affecting maintenance and difficult to control.

- More is the variety of an equipment, more it will make the maintenance difficult, tedious, irritating, complex and difficult to manage. Surely 100% level of interchangeability(IC) is difficult.

Defining Level of Interchangeability

1st Level IC

- Identical mechanical and electrical fitment with the number and size of securing fasteners and the cable size number and lugs.

- Identical Interface with the user about the menu and display

- Identical codification/symbols/nomenclature

- Maintenance free items with life more than POH periodicity

- Identical switch, fuses and operating handle/knobs and those items which are required to be replaced if opened for repairs.

2nd Level IC

- 1st Level IC plus

- Identical must change items, lubricants, bearings and condition base items such as auxiliary interlocks, wearing items having a high duty cycle.

- All those items which are considered for replaced during overhauls.

3rd Level IC

- Equipment manufacture in-house in Railway manufacturing units like bogie/traction motor/wheels/ etc. for which the manufacturing drawings are supplied and manufacturing and testing as per Railway drawing