Mechanized measurement and inspection – a help to cut down maintenance cost

Failure of integration of new technologies with the traditional system of working is the main reason for Indian Railways failure to cut down cost. Introduction of new technologies in any system cannot be done overnight and is always a well-planned engineering process. If not, both system runs parallel and not deriving any benefit to the organization. Measurement and inspection technologies developed during the last decade can benefit IR in cutting down maintenance cost of its infrastructure and bringing the integrity of measurement and inspection data along with conformity of maintenance work to improve reliability and safety in the rail system.

Present System of measurement and inspection

Manual Measurement of all parameters of

A track such as gauge, superelevation, twist, curvature, absolute vertical and lateral profile of left and right rail, unevenness, wear, MMD infringement

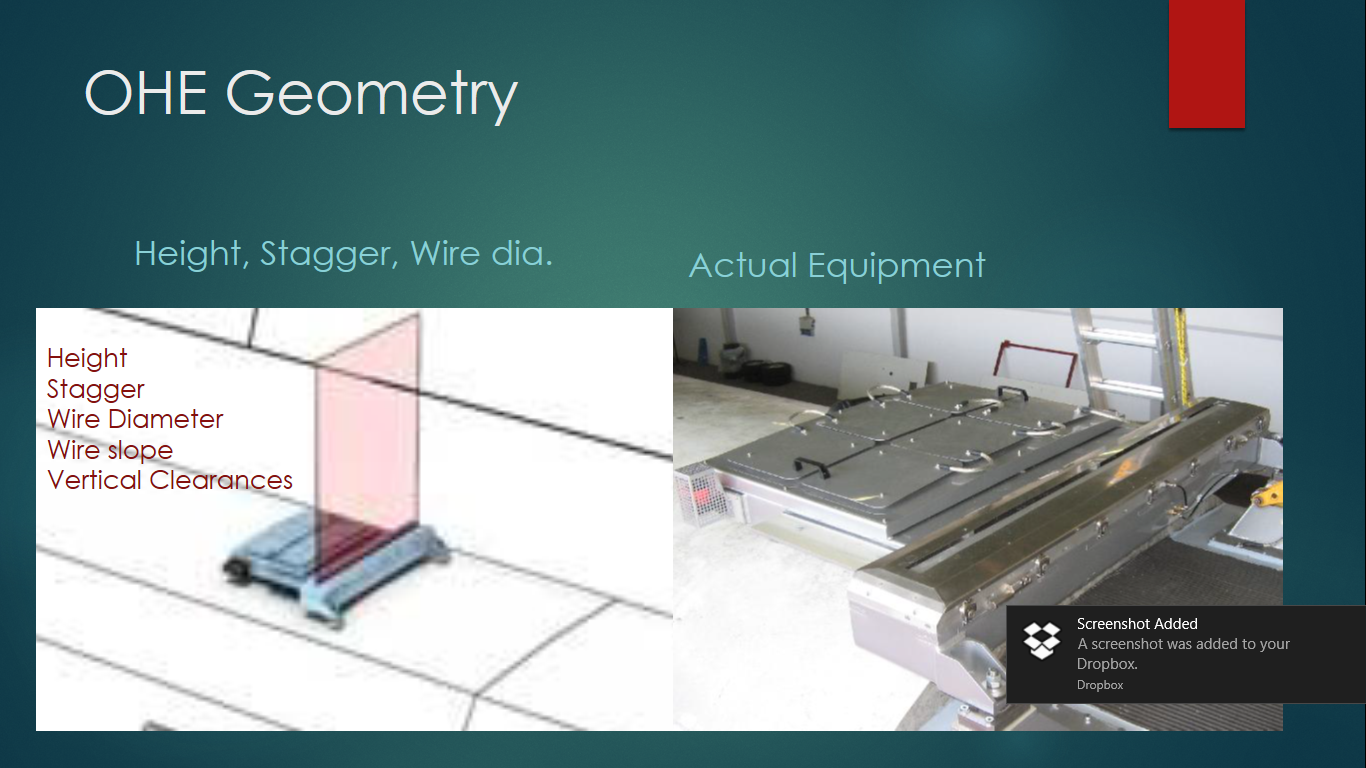

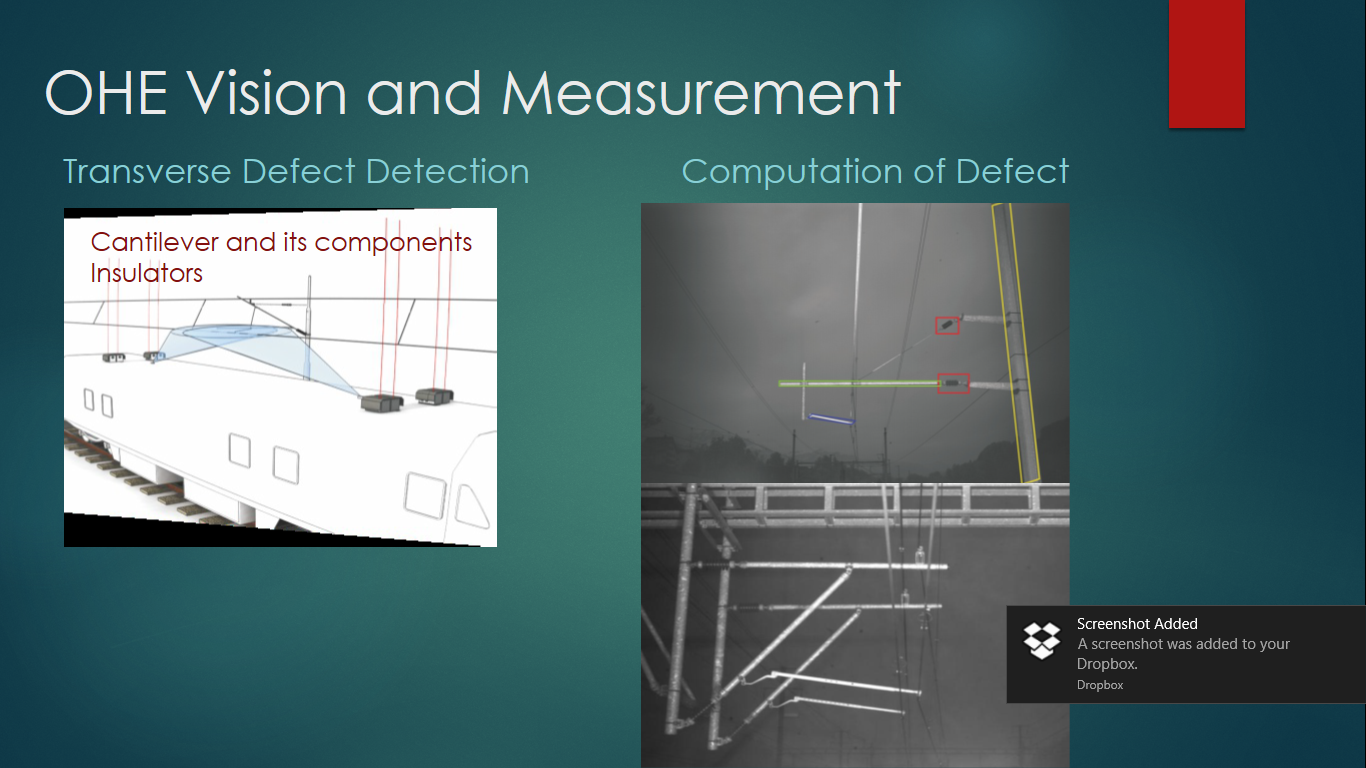

OHE such as stagger, height, contact wire diameter, the gradient of contact wire, measurement of implantation, measurement of clearances on overlaps, level of the auto-tensioning device, etc.

Visual Inspection for missing/loose/rotated/deformed

Track fastening fittings, alignment/broken sleeper, ballast profile and deficiency, cess profile, the degree of vegetation, etc. with daily, weekly and monthly schedule prescribed for a different level of the management system.

OHE for broken/flashed insulators, broken/missing droppers, missing structure, and cross bonds, mirror test for detection of contact loss and quality of the current collection, Auto-tensioning Device, etc. with daily, weekly and monthly schedule prescribed for a different level of the management system.

The inspection and measurement is done by the staff traveling on motor/push trolley for track and foot/tower wagon for OHE

Track maintenance based on the measurement/inspection and request for machine maintenance where not possible manually. Scope for manual maintenance is very limited. In the case of OHE, based on the measurement/inspection, the maintenance is done simultaneously.

Advanced measurement and inspection technologies

There are large many manufacturers developed supply track and OHE parameters measurement and inspection equipment with software to interpret the data on a user-friendly module. There also exists an EN standard for Track parameters i.e. EN 13848-1 to 4, however not for the OHE. The principle of measurement is a laser or optical light beam falling on the object and measuring the reflected light for drawing inferences on possible parameters.

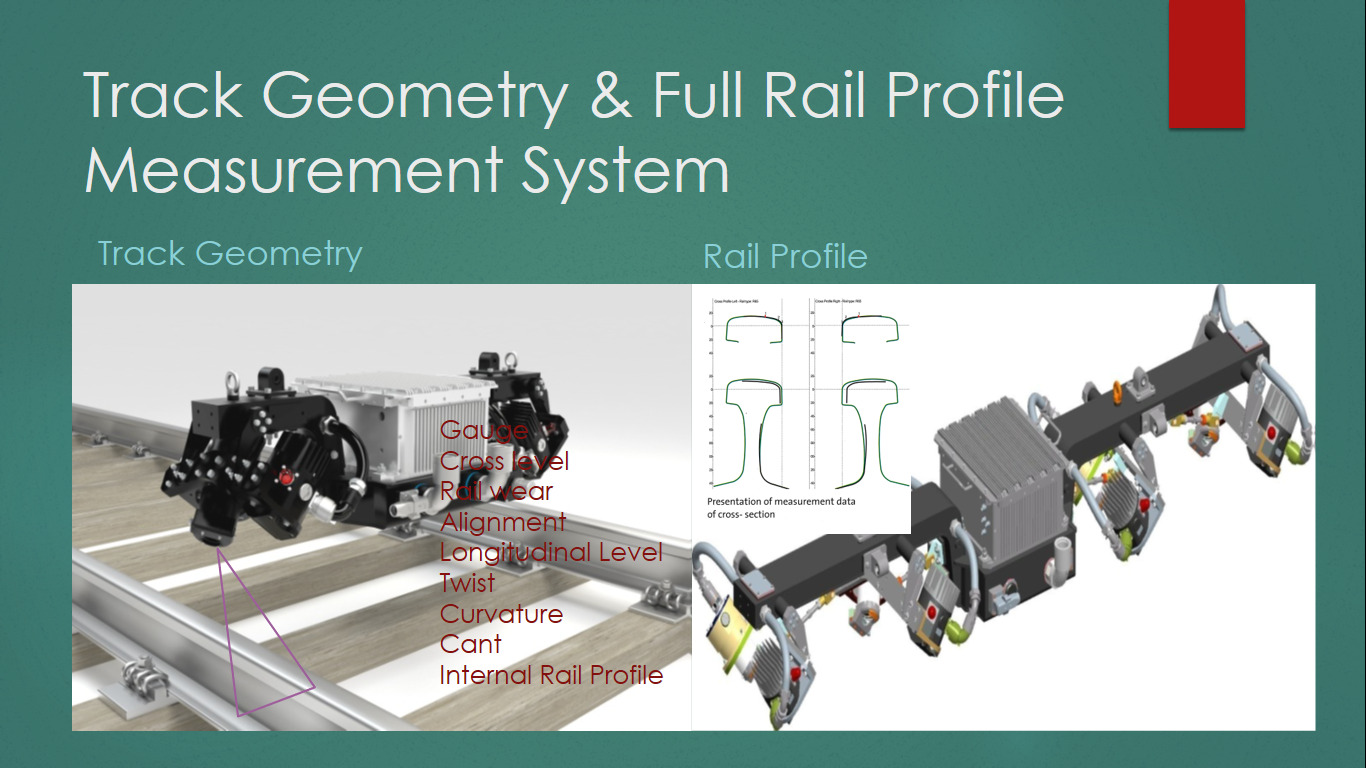

- Track and OHE Geometry Measurement System: Optical/Laser Inertial non-contact measurement of rail and OHE parameters

- Rail Profile check: High precision optical/laser based on the measuring principle of contactless laser triangulation and identifies defects on running edge and rail surface and assessment of reprofiling need.

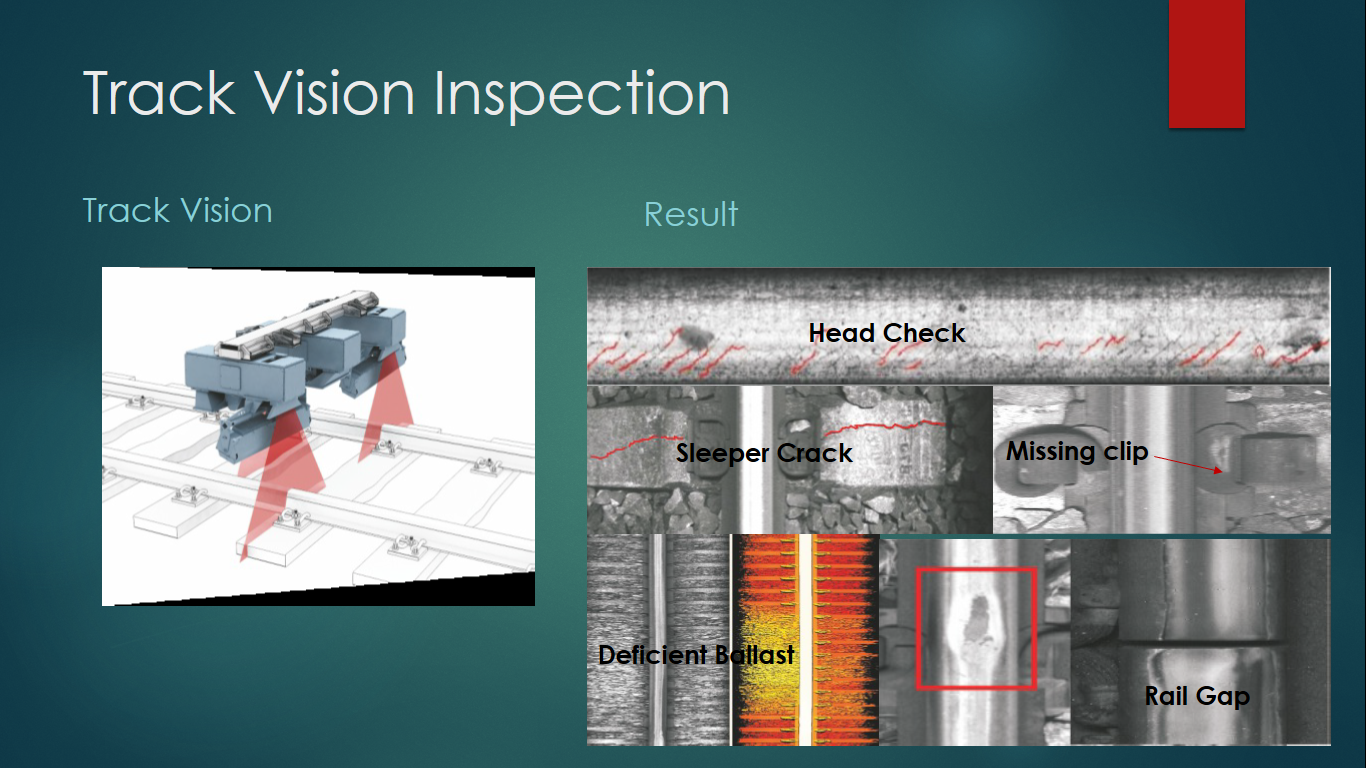

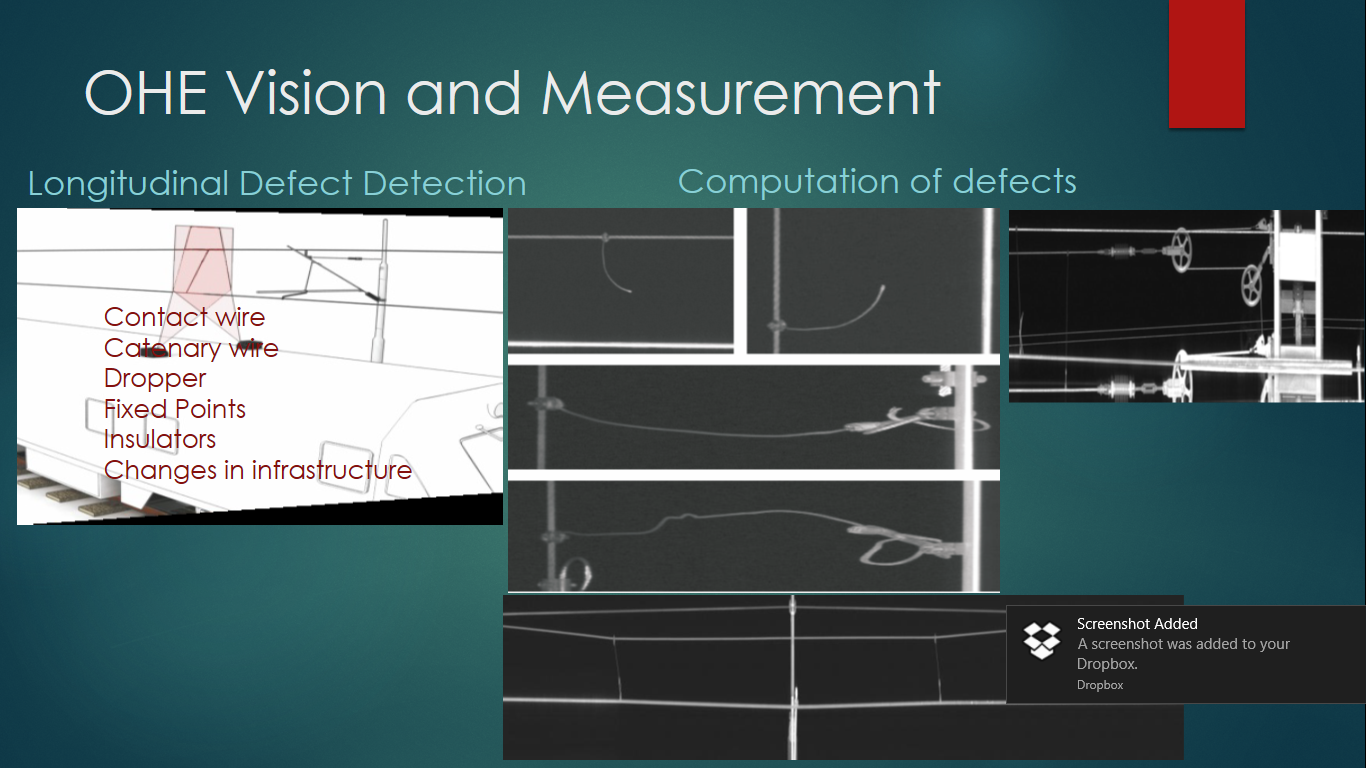

- High-speed digital cameras of resolution (2000*1000 pixels) image in real time (up to 700 frame/sec) processing inspection system providing automatic detection of any type of defect on track/OHE infrastructure.

- With laser technology, point clouding, and digital imaging, it will be possible to have three-dimensional imaging of the Railway infrastructure a great help in feature planning, integration of new projects/works etc.

- The possibilities of measurements and inspection are clear from the images below:

(Courtesy: Leaflet of Mermec, DMA and BySys etc.)

There is a very high competition in the International markets and the price will come down significantly depending on the quantity. In fact, there is every possibility of “Make in India” if the requirement goes up. The manufacturers whose document examined are Mermec and DMA of Italy, bvSys of Germany, Hitachi of Japan etc. All these sources are trying its best to penetrate into IR.

Status of advanced technologies over IR

Track

- Mechanized Track Measurement System is under the control of Track Machine and Monitoring Directorate of RDSO. It owns a coach equipped with TGMS equipment which runs at an interval (covering a territory of IR once in three to six month depending on the traffic wise route) and reports non-conformity to concerned zonal railway management for undertaking repairs. It is mainly a supervisory/auditing inspection

- 2 Nos. of Track Geometry Management System equipment procured from M/s Mermac installed on LHB coach (of which one is defective) is being used for the purpose.

- The current projects of IR at RDSO as available on its website

Development & procurement of High-Speed Track Recording Car

Replacement of two Track Recording coaches, two staff Cars and two track recording system of TRC 2500 & TRC 225

Finalization of Track Monitoring System specification which consists of Track Geometry, Visual inspection of Track, MMD etc.

OHE

- OHE Monitoring Car called NETRA under the control of TI directorate of RDSO runs at an interval (once in six months) and reports non-conformity to concerned management for undertaking repairs. It is mainly a supervisory/auditing inspection

- The current projects of IR

Online Monitoring System for OHE Traction Parameters in association with IIT/KGP

Technical Specification for self-propelled intelligent OHE parameter recording cum Inspection Car (Dhanwantari) Finalization of Monitoring System specification – Finalized Jan 2013

What is best for IR?

The responsibility of measurement and inspection by RDSO is not helping IR in reducing maintenance cost and improving measurement and inspection integrity. The following action shall pave the way for reducing maintenance cost

- Decentralization of Mechanized Measurement and Inspection system to Zonal Railways.

- Creation of Mechanized Measurement and Inspection Organisation at Zonal Railway HQ.

- Procurement of advanced Measurement, Inspection, Recording and Analyzing system for each Railway. There can be many options for the installation of this equipment such as

- Self-propelled vehicle either separate or combined for track and OHE

- LHB coach mounted with both track and OHE together or separate coach for track or OHE measuring and inspection equipment.

- Schedule of Inspection once a week. Vehicle attached to a coaching train in rear preferably a day time train and runs from one division to another or separate path if self-propelled.

- Each Division nominate its specialist staff to take the measurement and communicate the non-conformity for immediate attention to the maintenance organization to comply within 24 hours

- Separation of Measurement/Inspection/Defect Identification/Recordkeeping from the present system of combined responsibility of Inspection, Measurement, and Maintenance with one entity.

- Frequent check on compliance of maintenance work results in infrastructure integrity

- Traffic and OHE block for measurement and inspection not required and only for maintenance work

- Manpower for measurement and inspection not required resulting saving in cost of maintenance. Present average sanctioned manpower per TKM for track and OHE are 1.31 and 0.38 and can conveniently be reduced by about 25% beside utilising part of the staff for the newly formed organisation for mechanisaed measurement and inspection organisation.

- Foot patrolling system for Track and OHE to continue

- Overall Maintenance strategy shall be revisited, suitably dovetailing preventive, condition and predictive maintenance to reduce breakdown and improve reliability, safety, and life of the asset.

Capital and Running Cost

The cost of TGMS procured by RDSO was about INR 5 Crs. The cost of the LHB cost was separate. With this as a reference cost, the cost of the self-propelled combined recording car should cost around 50 Crs. but with procurement for each Railway, the cost will come down by 30-40% and also reasonable AMC, being a large number of units in service. The running cost will involve a few operators, fuel, and AMC which may not be more than 5 Crs. per recording car.

Conclusion

25% saving in manpower is an arbitrary figure. A work-study by the third party on the deployment of staff for the maintenance infrastructure will be an eye-opener.

This is the sure shot approach towards modernization of Indian Railways with gain in reducing maintenance cost, improving safety and reliability.

You may also like:

- ‘Rescue’ Indian Railway passenger business through statistical indices ‘RSKU’

- Indian Railway Context – Sanding to improve adhesion

- How Resistance is important in understanding Electricity?

- Where to begin to understand Electrical Engineering?

- Why IR passenger traffic heading south?

- Average speed of freight train over Indian Railways

Nice article thanks sharing this information, keep sharing