Energy Conservation -Traction

Traction Energy- Scenario

Indian Railways consumed 14.2 B-unit electrical energy and 2.6 B-liters of diesel oil for electrical and diesel Traction respectively during 2011-12. Responsibility for energy conservation in electrical energy lies with the electric department whereas for diesel oil with the Mechanical Department of Indian Railways.

Traction Energy

Energy for Electric Traction is consumed to overcome train resistance, grade and curve resistance, provide acceleration, losses in the locomotive during conversion of electric energy into mechanical energy and delivering at the point of contact and optimal use of auxiliary power in the locomotive for cooling of different equipment. There exists scope for energy conservation in many of the items and few of it are explained here.

Train Resistance

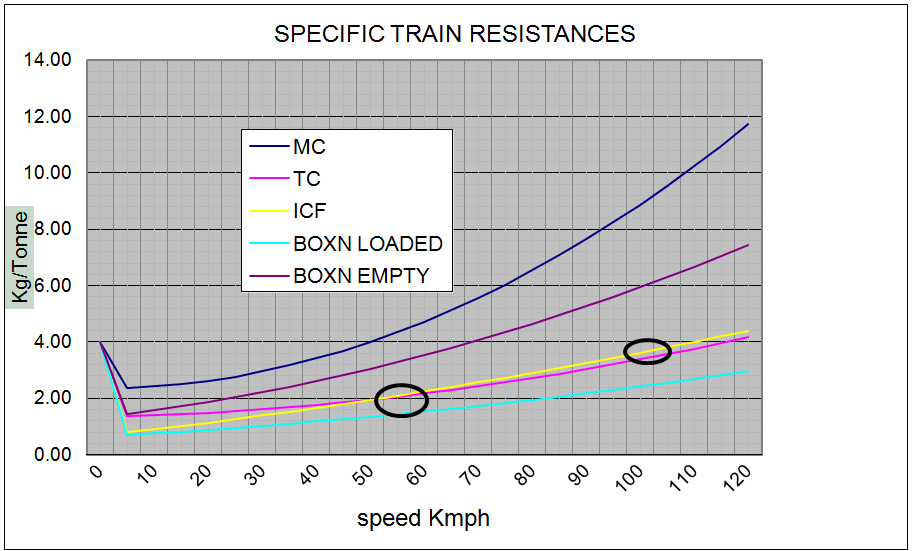

Energy consumed towards train resistance is specific to the type of rolling stock, track structure, speed etc. The formula used is a+bV+cV2kg/Tonne where a, b & c are constant depending on rolling stock and track structure and V is speed in kmph. RDSO has issued values of these constant sometime back in the 60s but no updating has been done since then to consider and evaluate the impact of many technological advancement taken place during the period such as change of the track structure and rolling stock. Steady drop in the SEC over the period confirms the positive impact. Train resistance vs speed for different types of rolling stock as per the prevailing formula is as follows:

Contribution of Train resistance in energy consumption in W-sec is given by Tr(in Kg/tonne)*W*(in tonnes)xgxD where Tr is average train resistance over the entire train journey of Distance D in meter. A 5000T train running with a train resistance of 1.5kg/tonne at 60kmph will consume 20 units of energy (excluding loco efficiency) for covering a distance of 1000m with SEC of 4.

Flange friction

Constant a depends on the vehicle and track profile whereas c depends on the aerodynamic profile of the locomotive for which not much can be done by the operator or maintainer. Factor b accounts for friction between the gauge face of rail and wheel flange. The friction is not continuous but depends on the frequency of sinusoidal rubbing action. Lubrication plays a vital role but there are not many studies done in Indian condition to evaluate the impact. Faster flange wear of the newly introduced BOXN wagon was observed in the year 1988 resulting derailments. Manual inner rail face lubrication was tried and successful. Impact on rail wear and energy consumption was difficult to evaluate due to the slow process of rail wear and no provision of energy meters on locomotive at that time. However reduced locomotive wheel turning arising were observed during that period confirming the advantages of gauze face lubrication.

Way side lubricator: Such Lubricators are mounted on the approach to curves where grease is pumped on the rail gauze face which is swept by the locomotive and trailing stock flange thus lubricating curved portion of the track. Way side lubricators for lubrication mainly on curves are in service.

Wheel flange lubrication mounted on the locomotive had not been successful. Retro fitment was tried in the mid 90s and thereafter it was decided to include it as part of new locomotive procurement. WAG9 locos were fitted with WFL but as it generally happens, that there were so many other problems associated with traction part itself, then who cares for this feature and finally get isolated, abandoned and then finally removed from the present manufactured locomotive.

The latest trend is to provide solid lubrication rod rubbing the flange continuously which transfer the lubricant to gauze face. This is has been provided on Metro coaches of Bangloure Metro Railways. An arrangement that exists on Banglore Metro is shown in the picture below

The system shall benefit Indian Railways with reduced wear, increased rail and wheel life, reduced energy consumption, reduction in noise level, improved safety management etc. Most important it takes care of the earlier problem of oil lubricant spilling over tread portion resulting loss of adhesion.

This is the most important area where extensive trial, analysis with different types of lubrication arrangement is necessary to finalize strategy to fight wear and saving on energy.

Grades

Up Grades and Curve Resistance contributes significantly towards energy consumption. Curve resistance is included in Grade resistance and termed as compensated grade resistance. Energy consumption in Watt-Sec on compensating grade is given by GcxWxgxD where Gc (compensated vertical distance per 100meter) is compensated grade and W is weight of train and locomotive. A 5000T train working on 1:150 gradient for a distance of 1000m will consume 90 units of energy equal to SEC of 18.

Regeneration provides an effective scope of energy conservation and has been harvested with the introduction of three phase technologies. The above train running on a down gradient with the maximum regenerative braking effort of 25T and balance pneumatic brakes will generate 48 units of energy (excluding loco efficiency) for maintaining the speed.

Up Grades are generally associated with downgrades as well. Driving techniques provide opportunity where coasting is done during up grade so that train rolls during down grade without requiring braking and speed not increasing maximum permissible. For this, coasting boards shall be provided on upgrade so as to get exit speed of 15kmph at the end of grade. Knowledge of velocity head for different grades is important. Velocity head is the height to which the train will climb if allowed to coast.

Energy savers are now being tried which directs the loco pilot about when to coast derived from inbuilt software assessing the velocity head, topology of the section ahead. In fact, Indian Railways shall consider this feature on all new design locomotives with the blending of air brake with regenerative brakes.

Acceleration

Energy consumption due to acceleration is given by WxaxD. Acceleration for different type of stock is 0.25-2.0m/sec2– Suburban, 0.15-0.25m/sec2 -Main Line and 0.05 to 0.12 m/sec2 -Freight and its contribution in the SEC can well be evaluated. A 5000T freight train accelerating at 0.06m/sec2 (or 0.216km/hr/Sec) for a distance of 1000m will consume 83 units of energy.

Unscheduled Train stoppage, speed restriction contributes to variation in SEC on day to day basis. There is a lot of scope for energy conservation in this area as can be seen from the energy consumed for acceleration. Speed restrictions and unscheduled train stoppage of coaching trains are monitored by Railway management on day to day basis as it affects time loss in train running as well. However, a system shall be developed to monitor and reduce unscheduled stoppage of freight trains to save on energy and reduction of wear and tear of the braking system. Equally important is that the reactionary force during acceleration and braking is absorbed by track adding to its maintenance requirement.

Efficiency of Locomotive

Efficiency of locomotive contributes significantly towards Specific Energy Consumption. Efficiency of locomotive is not worked out. Factors contributing towards energy efficiency of locomotive are current collection at pantograph, transformer, power converter, traction motor, gear mechanism etc.

The design of these equipments is generally energy centric because that improves reliability of equipment as well, therefore there may not be much avoidable scope for energy conservation. Design Engineers always look for economic application of new technologies which also has scope for energy conservation.

Efficiency of locomotive is generally in the range of 80-85% but there are no authenticated data on the subject.

Auxiliary Load

Transformer, traction motor and power converters use auxiliary power for cooling and is approximately 100kW used in all conditions of full, half traction load and coasting. This makes the efficiency of locomotive highly sensitive on loading pattern. There is ample scope in reducing auxiliary power energy consumption during half load and coasting.

Energy consumption towards auxiliaries can be controlled by sensing no and half load condition by traction power or temperature of power equipments and switching on and off auxiliaries accordingly. On tap changer locomotive, a modification can be done wherein cooling motors to stop on zero notch after a time delay of 1 minute and starts working as soon progressed to notch one. Considering average 20% of journey period either stopping or zero notch running, saving of approximately 100Crs is possible on available locomotives of Indian Railways.

With advanced instrumentation technologies, it should be possible to measure the tractive effort required and accordingly selection of number of traction motor sufficient to work the train to save on no load losses.

Three phase locomotive provides energy saving measures of regeneration during braking but the same is compensated due to continuous much higher auxiliary load. The auxiliary load review is necessary to take an advantageous position of three phase locomotive over conventional locomotive in terms of energy efficiency.

Data for Energy Conservation

Counselling of Loco pilot, benchmarking of energy consumption load and the crew run beat wise and monitoring of trend of energy consumption TSS-wise are important features for energy measurement and working out strategies for conservation drive in Railways.

Energy consumed train-wise from station A to B should be compiled continuously and benchmark the min and max limits of energy sufficient for the section be prominently displayed in the lobby. Loco pilots shall be encouraged to work within the band.

TSS-wise SEC compilation is of good help to identify route specific features responsible for higher SEC. This can also help in corrective action for which ROR can be worked out by estimating the saving in energy.

Impact of different factors on SEC can be studied from the formula of total energy consumption in Watt-sec as

277.8* (1.2W) (a1D1+…. anDn) +9.81W* (G1D1+.. GnDn) +W*9. 81*0.4 (C1D1+.. CnDn) +9.81*W*Tr*D

Where (C1D1+….CnDn) and (G1D1+..GnDn) are constant for a specific section and others to be worked out from speed chart, W is weight in tonnes, a in kmph/sec, D in meters, Tr in kg/tonne. Energy efficiency of the locomotive may be taken as 80% to compare it with actual consumption.

Energy Conservation during Maintenance

The locomotive is generally kept energized during testing thus consuming approximately 45 kW power. It takes around 4-5 hours for testing and repairs of which HT testing does not take much time. System of external air and locomotive battery supply to test the locomotive will help in reducing the pantograph raised time. The Maintenance in charge shall note the energy reading of a locomotive at the time of entering and leaving the shed and benchmark the minimum energy required per month for the purpose of testing.

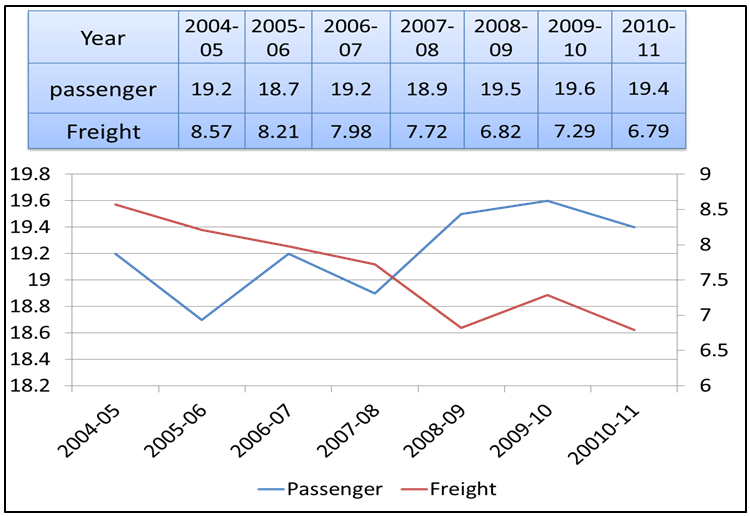

Status of SEC over Indian Railways

There is a steady drop in SEC of freight. Passenger SEC is taken as 20 and then Freight SEC is worked out. There may be some error in feeding passenger data but certainly there is a 20 % reduction in SEC from 2004-05 to 2010-11. Quantification of Specific action plan is difficult. However every item of the action plan has its value in the overall improvement.

Paste one table and curve

- 12951 Rajdhani Express consumed and regenerated 7241 and 744 units of energy respectively from Mumbai central to Vadodra, a distance of 392Km with assessed load of 1050T. SEC wroks out to be

[(7241-744)*1000]/(1050×392) =15.78

- Similarly 12951 and 12952 consumed 27010 and 26390 units whereas regenerated 2658 and 3000 units of energy covering a distance of 1400Km and load of 1050T with SEC of 16.6 and 15.9 respectively. 12952 consume less energy and also regenerate more because of long sections of down gradient in Ratlam Division. Average per Km consumption is assessed as

- A data of 100 trains can help in benchmarking the energy consumption; a loco pilot shall work with.

please share SEC figures of Nagpur division of Central and Nagpur division of South East Central railway