Understanding electical cable and and its role in fire

Cables are used for transport of electric power from one place to another with freedom to take it through any available space. Transmission of electric power through cable has the following advantage over overhead wire

- Very less right of way

- Lower visibility

- Minimum effect due to bad weather like storm etc

- Aesthetic with clear sky view

- Suitable for thickly populated area

- No alternative when house and infrastructure wiring

- No alternative when it is difficult to dig trench and inadequate clearance for overhead wiring

But

- The cost of installation is much higher

- Less life as compared to overhead system

- Delay in identification of defect and more time to repair

Use of Cable in Transportation Business in Rail base transportation business

Cables are widely used in fixed or moving infrastructure associated with rail base transportation such as Indian, Metro and Tramways. There may not be any application where cables are not used, and therefore, a must for every Electrical Engineer to understand its simple design features to avoid mishandling. Cost of cable used in an underground and elevated station is around metro station is about 10 and 1.2 Crs. . Electric and Diesel Locomotive, Electrical Multiple Unit, Metro Coaches, Air Conditioned Coaches, Traction Sub-station etc. are most important usage area of cables for rail transport. But beside the financial stakes involved, most important is it role in originating or propagating fire. This is the first and most responsibility of any Engineer to be careful about.

Features of Cable design:

A cable design consists of conductor, insulation, sheath, armour etc and a few more items for special cables. Current passing through the conductor experiences resistance and loss of energy equal to I2R and this loss of energy is confined within insulated covering and raises the temperature of the conductor and insulation. The thermal conductivity of the insulation 0.17 and 0.25 for PVC and PE respectively along with its resistance decides the temperature rise of the conductor. The permissible limit for PVC and XLPE materials are 700 and 900C respectively. Working at a higher temperature for a longer time deteriorates insulation. Short term temperature rating of conductor if goes more than 100-1200C, it will melt/soften the insulation. This will result in breakdown of carbon atoms, which then will act as a semiconductor increasing the leakage current with smoke and fire situation. Therefore, there are few things which are very important in cable designs and installation.

- Sizing of Cable to make sure conductor temperature within permissible limit

- Protection of Cable to protect from overload and short-circuit current through it

- Selective property of low smoke, zero halogen and fire-retardant

- Low level of smoke so that visibility of people to reach safety is not impaired

- Low level of HCL. Level of 10%-25% is termed as irritant and more than 25% as corrosive. Zero Halogen cable emits only 0.5% of HCL.

- Ingredients are added in the compound like Hydroxides which emits water when cable is subjected to flame thus retarding its propagation.

- Fire resistance cables are different to fire-retardant. Fire resistance cables are exclusively used for maintaining the circuit integrity for fire fighting services. These cables are lapped with mica tape over the conductor and works at 9500C temperature maintaining the circuit.

How the Cables are sized?

- Current carrying capacity of the cable is given by the standards based on the permissible temperature rise. The standard provides a margin for current carrying capacity based on different installations technique stated as following:

Up to and including 16 sqmm

- Cable in a conduit in thermally insulating wall

- Cable in conduit on a wall or in trunking (Appx. 20% more than a above)

- Cable tied with clipped method (Appx. 40% more than a above)

Above and including 25 sqmm

- Cable taken on a perforated cable try horizontal or vertical (Appx. 5-10% more than c above)

- Free Air on horizontal flat space or Vertical flat spaced ( Appx. 20% more than c above)

- The cables are sized at an ambient temperature of 300C and current capacity of the cable to be de-rated depending on the ambient temperature as prevailing on the working situation. BS7671 describes the de-rating factor which is around 1.02 at 250C and goes down to 0.82 at 500C and 0.35 at 850C for thermosetting insulating material (Operating Temperature 900C). This describes the sensitivity of the cable carrying capacity to ambient temperature.

- There are 19 methods described for installation of cables. The purpose to check for conductivity of heat from the cable to the surrounding surface. Number of cables grouped and the installation method selected plays an important role and one shall examined for a cost-effective installation method.

- The load on the cable is worked out by summing up the loads in kW of each appliance and calculating the current considering pF of 0.8. When we provide automatic power factor corrector at load end to improve the pF to more than 0.95, only active current is supplied through the cable and reactive current by the APFC at load end, therefore, the current through the cable get reduced by about 15% making a difference to the sizing of cable.

Construction of a Cable

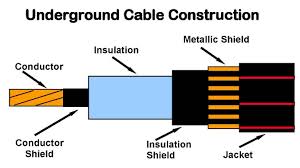

It is important to understand the construction and its features to derive best performance to meet the application. A cable generally consists of conductor, conductor screen, mica tape for fire survival property, insulation, insulation screen, insulating material, insulation screen, conductor sheath, filler, bedding/inner sheath, individual screen (instrument cables), armour, outer sheath, termite protection etc.

Conductor: It is either annealed copper or Aluminium. As a thumb rule, electrical equivalent of Al have a cross-sectional area of about 1.6 times more as compared to Copper. It is generally stranded to meet the property of flexibility and reduced skin effect. Annealing is the process of gradual heating and cooling to make it more malleable and less brittle. Bare Cu is coated with tin, nickel, silver etc. to prevent the insulation from attaching or adhering to the copper and its deterioration due to higher temperature.

Conductor Screen: It is a semi-conducting tape to support a uniform electric field and minimise electrostatic stresses applicable in MV and HV, EHV cables. A semi-conducting cross-linkable compound applied under simultaneous triple extrusion process over the conductor along with the insulation and the insulation screen. The triple extrusion is a single high precision operation that eliminates the possibility of any contamination between the layers which could create irregularities in the electric field. The extrusion process is either through catenary CV (CCV) or vertical CV (VCV) line.

Insulation: There are two types of insulating material commonly used namely thermo-plastic Poly Vinyl Chloride (PVC) and thermo-setting Polyethylene(PE) and cross linked PE XLPE).

PVC mixed with plasticisers is widely used for insulated cables. Low voltage coper conductor PVC cables are extensively used for domestic home appliances wiring, house wiring due to high tensile strength

PE has excelled properties at room temperature. During cross linking, the individual polyethylene chain movement is restricted on each other due to cross linking. The cross linking helps in retaining the excellent property of room temperature at higher temperature. The useful property of XLPE is resistance to temperature, pressure, environment stress crack, Ultra-violet light, chemical and oxidation. It has following more advantages –

- Higher current carrying capacity as it can withstand higher temperature of 900C as compared to 700C for PVC

- It has higher overload capacity, lower di-electric and constant power factor.

- It is lighter in weight and smaller bend radius making installation easier.

- Insulation size is thinner but the resistance is higher. Volume resistivity (ohm-cm) of PVC is of the order of 1014 as compared to 1017 for XLPE making it 1000 times better.

- It has higher moisture and chemical resistance

Elastomeric and Rubber insulated cables are preferred for flexible application and in congested locations here the bending radii are very small. They are used in special applications like, mining, ship wiring, transportation sector, locomotive and defence. There exists consistency in batch to batch variation in weight and metering components.

Insulation Screen: This is a layer of semi-conducting cross-linkable compound which will be applied by triple extrusion process over the insulation during manufacturing of MV/HV/EHV cables. It has similar function as that of conductor screen

Laying-Up: For three core cables, the three cores are laid up with non-hygroscopic fillers like polypropylene fillers at interstices and a binder tape is applied with an overlap to keep the three core intact. These binder tapes may be of PVC or foamed polyethylene. Extruded Inner sheath of PVC or PE is applied over laid up cores for armoured cables.

Armouring: Armour is provided over the inner sheath for mechanical protection of cable with ability to flow fault current in case of fault. It is provided helically over inner sheath. For single core it is of Al ( to prevent generation of current through electromagnetic induction) and for multi-core it is galvanised steel.

Oversheath: Extruded layer is provided over the armour and over the laid up cores in case of un-armoured cables. Outer-sheath material can be PVC, PE or XLPE. Colouring is given as per the need to the outer-sheath. An anti-termite formulation is given to over sheath considering the need.

Test in cables that matters for its life and reliability

Diameter of wire and its resistance in ohm/Km corrected to 200C, Annealing test to check its flexibility, thickness of insulation and overall diameter, test of insulation for its compound/tensile and elongation with or without aging/hot pressure test/hot-set test/ ozone resistance test/ conductivity/ corrosive and acid gas test etc. Test under fire condition and specific to the need of LSZH cable along with toxicity index and smoke density is important for all applications where such conditions are specified.

Role of a cable in an incidence of fire

Selection of right cable, its sizing, testing and installation all put together plays a vital role for in-service performance of the cable. During any fire incidence, cable performance is always a subject of doubt and comes under scrutiny by forensic department.

Cable itself initiating a fire is generally due its overloading during which the cable core temperature goes high, softening of the insulation and it cracking. This results in increase of leakage current and continuous overheating till such any protection to work. In case there is an inflammable item nearby which get ignited because of the temperature rise, it results a condition of fire. The other factor is when there is a loose connection at the terminal. The loose connection results in heat due to higher ohmic loss and rise of temperature. Thermal conductivity of copper is 385 W/mK as compared to less than one of air. The heat generated will travel faster through copper conductor and raising the temperature of the cable adding to creation of conditions for smoke emission and fire.

Cables when subjective with external fire shall not add to smoke and corrosive gases into the environment to cause inconvenience in the fire fighting process.

Important of cable in causing fire accident can well be estimated that “Fire in cables led to accident in submarine INS Sindhuratna, Navy says” Read more http://timesofindia.indiatimes.com/india/Fire-in-cables-led-to-accident-in-submarine-INS-Sindhuratna-Navy-says/articleshow/31336637.cms

You may also like:

- Electrical accidents waiting to happen…

- Indian Electricity Rules, 2005 defines the basic fundamentals of Electricity…

- How to be confident about safe use of electricity?

- ‘EARTHING’, a must for every one to understand its importance…

- Electrical Protection System -Train Lighting and Air Condtioning

- Electrical Protection System – Tap Changer Locomotive