CLEANING – first step to maintenance

A large number of products of Indian Railway work in very harsh environmental condition. Environmental conditions like dust, moisture, chemical pollutants, rain etc. create natural cleaning need and can be addressed with little effort. But the problem is aggravated due to external factors prevailing all over Indian Railways such as

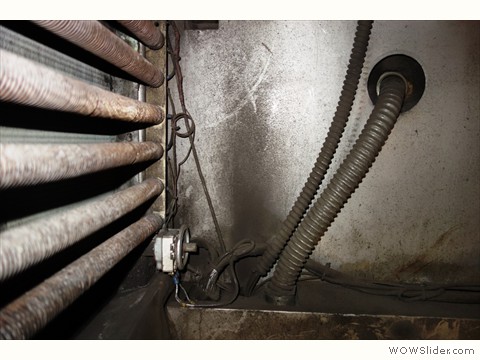

- Poor infrastructure for disposal of garbage which lies on the track and sucked by the equipment mounted under-slung

- Accumulation of dust on oil leaking from the equipment which is commonly observed in a large fleet of rolling stock

- Application of lubricants on the wearing surface which is exposed to environment resulting contamination with dust

- Cleaning process deployed is by blowing dust in the environment, wiping with k-oil or petrol etc.

When WAG1 locos were imported along with technology transfer and maintenance infrastructure created at Electric Loco Shed, Tatanagar, one of the machinery plant procured was vacuum cleaning of inside of the locomotive by blowing dust and sucking it by vacuum plant. This plant could not work due to continued water shortage. Traction motor blower unit of locomotive was installed to create a draft to suck the dust. This practice is widely used but dust collection is still an issue. With the development of technologies for vacuum plants for cleaning purpose, it should be in fitness of things to revert back to provision of vacuum plants for cleaning.

Cleaning is the biggest challenge in Indian Railways whether it is Railway station or workshop/shed/washing line. Cleaning is always considered a low end job which can be performed by unskilled staff or outsourced. Application of technology in holistic way has been considered only in a limited way. There are expertise available in mechanized cleaning which can address all needs such as to

- improve cleaning standard

- reduce dependency on manpower

- ensure dust collection and disposal instead contaminating the environment

- prevent wastage of lubricant and its reclamation

- reclamation of water

K-oil and petrol are generally used as cleaning agents. Cleaning agents are available based on brand value which is difficult for Govt. organisation to consider without offering competition. Different cleaning agents are recommended for different need such as

- electrical contacts

- pneumatic values using rubber components

- oil and grease

- dust and rust

- simple cleaning agents for glasses

therefore will require specification for each application along with list of approved sources.

Machinery and Plant for any maintenance organisation will require mobile and stationary cleaning machines unless it is decided to go for outsourcing of the machine and manpower.

Prevention is better then Cure

Prevention reduction of cleaning need can also be handled by incorporation features in the design which not only reduce cleaning need but will certainly increase life of the asset. These can be

- Use of stainless steel boxes for under slung mounted equipment such as Alternator, ERRU, Batter Box etc.

- Designing for drain water flow so that it should not passage into equipment or accumulation any where

- Leak proof design of gear case; the saving on lubricants itself justify the high cost if any

- Improved level of surface finish to prevent accumulation of dust, pollutants etc.

Share your idea on cleaning to benefit all those involved with maintenance.

You may also like:

- Statistical Tools for Maintenance Engineering

- A way forward to improve designs for sustainability of a…

- Standards method of Symbol for Units of Measurement

- Condition Based Maintenance – a cost effective approach

- Understanding Maintenance of Fasteners

- Condition based maintenance with M2M Bigdata Analytics