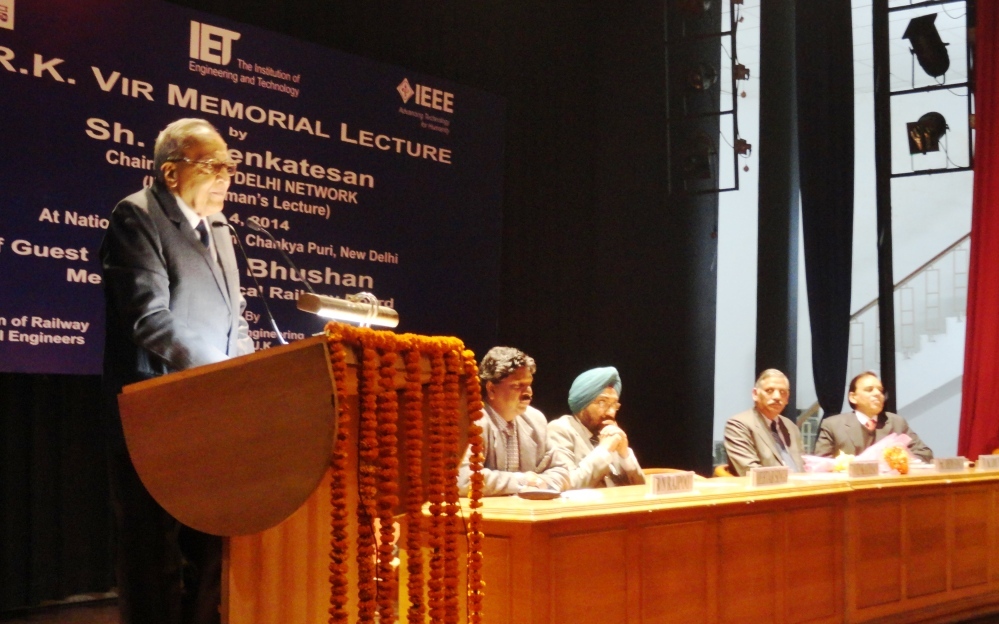

Memorial Lecture by Sh. N.Venkatesan Former Member Electrical Railway Board

The Institution of Engineering and Technology organised “IET Chairman’s Lecture” on 4th January 2014 supported by IREE and IEEE. Sh. N. Venkatesan, Former Member Electrical, Railway Board & Chairman IET/DLN, Professor Bhim Singh, Chair IEEE & HOD Electrical Department, IIT Delhi. Sh. V K Dutt, Former Additional member/Electrical, Railway Board & Sr. Member IEEE and Sh. Mehtab Singh, Genl. Secretary/IREE and CEE/N.Rly and Fellow of IET & Chartered Engineer were the distinguished dignitaries on the dias.

Former Member Electrical Mr.Venkatesan speaks out his mind while delivering memorial lecture. It is summation of his knowledge which otherwise you will not find a mention in any text-book that makes the lecture worth reading.

Good Morning ladies and Gentlemen,

At the outset, I wish to state that I consider it a great honour &privilege to be invited by the august bodies to give the lecture on the topic “Electrification & Challenges on Indian railways”

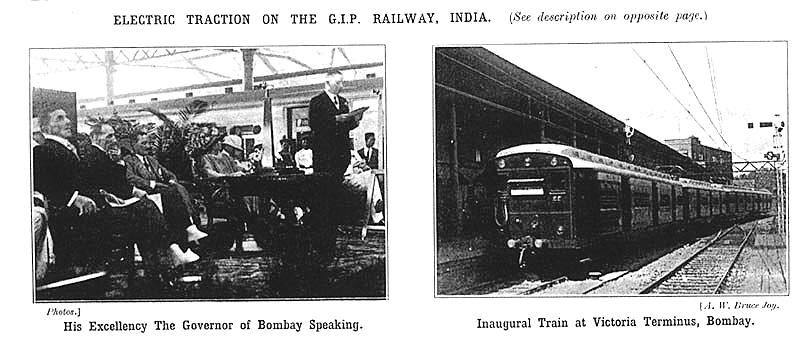

We must remember Electrification of Indian Railways started on 1500v DC system on the Kalyan Bombay VT-Kalyan in 1925, later extended over Igatpuri-Pune Ghat section of the old GIP Railway & the suburban system of the BBCI Railways from Church Gate-Virar section progressively. I joined C Railway as a probationer in 1957 & under training in the system, started admiring the vision of the original designers & planners.

Way back from 1930’s, the substations was remotely controlled from Bombay VT on simple DC pulse systems & Electro –Mechanical telephone Strowger switches. Rotary AC/DC Motor converters, deriving supply from 110 kV AC Railway’s own transmission system fed 1500V DC to the catenary. Resistances were brought in & cut out later, while starting the motors, with remote control. This system worked near Railway for 50 years till it got replaced by modern SCADA System around 1991.

The OHE & locomotives were built robustly with British origin & a conservative approach to Design margins. There was an interesting Swiss design of a small fleet of steam locomotive inspired Jack Shaft Drive coupling all the wheels. The Locomotives had given more than 50 years service, till replaced by CLW built Locos

Railways had set up their own Power House at Thakurli to generate power for the traction system. In fact, it used to give peak power to Bombay city requirements. It was unfortunate we could not replace the plants & closed the power house in 1990’s, a costly mistake when we find Electricity Boards are now charging abnormal high tariff for Electric Traction.

In fact, in 1991, during Janata Regime, Hon’ble Prime Minister Shri VP Singh wanted our Railway Minister Shri George Fernandez to examine whether Indian Railway’s could consider setting 4 MW power project (1000MW each) in different zones as there were frequent problems of strikes in U P Electricity Boards at that time. I mentioned to Shri Fernandez that IR had much experience even in coal mining during steam days & experience with Chola Power House. There was resistance from the Power Ministry to the suggestion. Within Railways also, there was an opposing view that Railways should concentrate only on its core activity i.e. transportation. There was the experience of Railways vertically integrating with Power Generation as in the case of Hong Kong, Japanese Railways etc. The proposal could not be progressed much due to falling of Janata Govt. The Power Secretary then mentioned to me, that considering Maharashtra’s Peak hour shortages, Railway may consider a gas base plant at Thakurli but gas was in short supply.

Subsequently IR has taken equity investment in Power plants with NTPC, to avail benefits of lower tariff permissible to captive generation users taking advantage of Indian Electricity Act 2003. I think it makes sense for Railways to take stakes in Power Generation further to control input costs & it should be possible to justify that the investment can give adequate returns. Yes, there is a problem of several competing demands on Railways scarce capital resources.

In the middle of 1950’s decision was taken to electrify Calcutta Suburban system on 3000V DC, an up gradation over older 1500 V system, to handle increased traffic density & following developments in Europe and South Africa. Some of us, as probationers from C. Railway, were transferred to Calcutta Electrification Project in mid-1957. The first phase of the project was inaugurated by Shri Jawahar Lal Nehru in Dec. 57 from Howrah to Sheoraphali & he spent some time in the Driving Cab. There was an interesting issue, I recall that evening of the inauguration when Eastern Railway held a Dinner in honor of Late Shri Jagjivan Ram ji, who was the then Railway Minister. Babu Jagjivan Ram during dinner, after conversing with Board Members & seniors, strayed away to our group of probationers standing in a corner. I just mentioned to him the day we were inaugurating 3000 V DC system, there was news that the Railway Board had decided to adopt 25 KV AC traction system & that the Calcutta project would need to be converted on 25kV AC. He jumped & said, “Who told you Railway Board took the decision?” They could not take the decision; I had to intervene to decide on AC system. He said, “I know AC is better than DC, I have studied Physics in my graduation during my Jail imprisonment”

I recalled this to Shri PN Murthy the then GM Railway Electrification, when he visited CLW in 1967 to see the progress of Elec. Loco &Traction Motor manufacturing Project. Shri Murthy was CEE/E Railway in mid 1950’s and one of the few officers allotted to Elect. Dept from Jamalpur cadre. As the senior most CEE in IR cadre, he was drafted to Railway Board as an officer on special duty to progress collaboration with French Railways on 25 kV traction. He said the adoption of AC system was vehemently opposed by CEE’s of Central & Western Railways as they felt DC was superior. AC system was new &untested anywhere else. Based on their advice, the Board got divided, unable to commit to the new system. As the bilateral agreement with French Govt. was getting delayed, the Minister after reviewing took the bold decision to opt for 25 kV AC system, a momentous decision which proved right as progressively all Railways in the World adapted 25 kV as the standard System. It is a great example how momentous decisions, evaded by specialists are ultimately taken by people with sound common sense.

I was posted as an Asst. Elect Engineer/Railway Electrification in CKP Division of S E Railway & later became Ex-Engineer/RE. I was in-charge of construction in the initial phase of steel-belt electrification of Railways on 25 kV system of Tata- Rourkela, Dongaposi-Rajkharswan-Adra sections. I was fortunate to be associated with the commissioning of the first section on IR on AC system on the Kendposi section of Rajkharswan Dongaposi line in Dec 1959. The French Railway in my opinion gave us one of the finest OHE systems that has stood the test of time over 50 years. We took supply at 25 kV from Electricity Boards in the initial phases, later we set up sub stations at 132 kV & above, have even been running power lines along the track e.g. in ALD Division first time.

One weak point of the French collaboration was, however, design of a WAG1 class of Loco which failed on the steep grades of S E Railway due to adhesion problems. Generally, French equipment was marginally designed compared to British practice. This class of Locomotive, the French said had given good service on the SNCF in iron ore areas. The reserve capacities were however not adequate in the Locos to face adverse track conditions, harsh foggy, wet environment & oily leaves falling on the track. Indian Railways decided to go for a hybrid diesel CO-CO bogie design called WAM4 series. We happened to discuss the issue, 25 years later with Mr. Nouvion, considered the father of High Speed Traction in French Railways as head of Design & Development, in a seminar in Delhi on RE. He confided that there could be mistakes on their side. He said that French Designers, in the initial phases of 25 KV traction in France, were cutting corners to cut costs to justify Electrification. Looking back, I feel Electrification particular Railway in SE graded sections did not acquaint itself very creditably in the initial phases.

There is a lesson for all Elect Engineers here, in drawing specifications for locos or equipment, we need to mention the practical track variations expected, variations in voltage, frequency in power supplies, harsh environmental conditions, extended warranty for equipment etc. We need to build reliability of equipment at design stage itself. Taguchi, the famous Japanese Statistician, talks of the concept of “Robustness in Design” has, evolved several approaches to reliability measures, a practice now widely adopted by major manufacturers globally. Quality System QS- 9000 of US Auto manufacturers call for FEMA (Failure Mode Effect Analysis) of all auto components at the design stage. I am sure RDSO will be including Reliability studies in specifications.

I had to face with another environmental problem when I came to the Board as Member in 1989. When we were desperately battling to bridge Nagpur-Itarsi and Durg-Bhusawal section electrification on the N-S & E-W routes, we were confronted on the RE (S&T) side with the problem of insulated optic fiber cables (laid in HDPE /PVC conduits) being attacked by rodents. The European supplier of cable first disowned all responsibility & maintained that the cables conformed to international standards, they had added toxic resins to repel small mice’s as in Europe but Indian Rodents were abnormal . Luckily, there was a clause in the specification that the supplier should study the local conditions in cable laying which rescued us. The Danish Supplier finally agreed to take out 30 Kms of cable laid already, send it to the Allahabad plant of Hindustan Cables, who had a collaboration agreement to manufacture optic fiber cables in India. The firm clad the cables with steel tapes & send back for relaying. The later Specification for optic fiber cables was modified to include steel taping. In those days, we even toyed with the idea of suspending optic cables on OHE masts, but came a news item that in Australia there were damages by wood pecking birds

While the crisis was in progress, I confided the problem with Railway Minister Sh George Fernandez showed him some samples of cables bitten by rodents. I also thought it was fitting to appraise the Minister, should this issue lead to delays in Electrification programs. Sh Fernandez asked me to leave the samples with him. The next day he called me & said he discussed the matter with Shri Devi Lal, the then Dy. Prime Minister, who told him that these were day-to-day problems farmers like him faced. The Railway Engineers were living in Ivory Towers; they should step out consult farmers on the environment. We managed to close N-S and E-W electrification almost in time

I joined Chittaranjan in 1965 in the Electric Loco Traction Motor manufacturing Project after completing Mughal Sari Allahabad Electrification project. I was deputed for manufacturing training in Alsthom & visited other Group partners like Siemens, AEG Germany. The manufacture of MG 1580 HP traction motors for WAG4 Locos of Chittaranjan motors was quite successful, but later by the decision to build Co- Co Bogie WAM4 Locos; we landed up in problems with TAO 659 Motors, with Armature windings flaring up during over speed tests in the Test bed itself. Alsthom, our collaborators blamed CLW for poor manufacture. But then imported armatures in service on SE Railway also started failing due to armature banding burst cases. Alsthom accepted responsibility for failures but stated these were mistakes in their own Mfg, not willing to admit design failure as it would have brought down Alsthom’s image internationally. They took back 100 armatures supplied in SE service, progressively back to France, changed the design of the Armature conductor as a monolith section to improve vertical stiffness instead of multiple conductors used earlier to reduce eddy current losses. CLW later changed the design correspondingly & CLW lost one year of production. In fact, CLW produced some Locos with DLW supplied motored bogies-a hybrid of AC loco super structure & Diesel Loco BHEL motors, lower in HP but tolerated for exigencies. During the period of Diesel motor use in Electric locos, the Chief Designer of Alsthom, Mr Jouy-very reputed as a TM designer visited CLW & during shop rounds saw the heavy diesel motors, 3.2 t against TAO 2.2 T TAO fitted on bogies &asked how such heavy motors were allowed on Eclectic Locos. How could IR get quick supplies of motor? I explained these were its own supply for Diesel Locomotives. Mr. Jouy said at the initial stages of TAO- Design, IR was putting pressure on him to reduce un-sprung weight to allow locos for future higher speeds in passenger operations. If only he had been allowed little extra weight, he could have produced a very sturdy version. This was an important lesson to us.

IR/RDSO had adopted reduced temperature rise requirements (IEC-20degrees) but seeing large scale failures of motors as also transformers, I felt whether we should reduce to -30degrees and add more steel &copper in motors & transformers than adding steel ballasting in locos to improve adhesion. The failure of TAO motors later led to collaboration with Hitachi for a stronger motor for Locos at Chittaranjan & this series I think has become the anchor of our freight operation.

CLW distinguished itself in manufacturing the first fleet of indigenously built DC Locos with imported traction equipment for C Railway in early 60’s. The philosophy of mechanical shell was derived from the 3000HP English Electric Locos used in Calcutta Electrification. The first loco turned out from Chittaranjan was christened as “Lok Manya” after the great Indian freedom fighter Shri Lok Manya Tilak by Sh Jawaharlal Nehru. Shri Hattangadi, who had great experience in C Railway as DEE/RS in BB Division of C. Railway, was specially brought in to lead the Project. I joined him later on the AC Elect Loco project, which he brilliantly led. Mr. Hattangadi was a great mentor to me with his deep commitment to Quality &Reliability

CLW later produced in early 70’s a DC fleet for C Railway using the AC shell. An AC motor-DC generator was imported to give supply for AC auxiliaries developed for AC Locos. There were much problems in frequency control of these MG sets in service. Rheostat braking was introduced for C Railway Ghat operation &later adopted for SE Railway grade operation. Later AC/DC loco version was developed for Igatpuri-Bhusawal extension & AC electrification beyond Virar on W.Railway. Notable features of this design was use of 2 separate pantos for AC-DC operation and use of AC/DC sensing devices. Later on in early 2000, CLW has done extremely well into production of indigenised ABB 3 phase locomotives

On the EMU side, RDSO & ICF distinguished themselves in developing 1500 V DC stock for C and W Railways from late 60’s using Mechanical shells derived from conventional Sechreon coaches & the imported DC stock in operation in C and W Railways. Import & indigenisation by BHEL provided the support for Traction Equipment. Special mention should be made about development of 12 feet wide bodied stock to tackle Bombay suburban rush. There were much failures of BHEL motors in services, modifications attempted, but with little success. Later we imported some motors from Fuji Elect &put in service in E Railway

ICF also developed 25 kW BG AC EMU stock for suburban operation in Calcutta and Delhi besides developing a small fleet for the Chennai Meter Gauge system. Equally good work was done by RDSO, Eastern & C Railway in the 1970’s in converting the released 3000 DC stock for 1500 DC operation due to conversion of Calcutta Suburban to AC. Both Central & Western Railways have distinguished themselves along with ICF in developing 25 kV AC/DC stock for Mumbai Suburban AC conversion project in the last few years. I would like to congratulate Western Railway for successful completion of AC conversion & Central Railway for Ghat section conversion which must be giving immense benefits to freight operation. Our Chief Guest Sh Kul Bhushan can always look back at these accomplishments with pride as he headed W & Central Railways during crucial periods.

IR needs to be congratulated for taking the bold decision to convert the old 1500 DC system in Mumbai to AC. The bold proposals came from C Railway during my tenures as ML. Post retirement, in 1995-1997, I was associated with a Group of German consultants appointed for the World Bank Loan for the Rolling Stock part of the Mumbai Urban Transport Project. The technical support team of WB in Washington comprised mostly of Engineers from USA who were influenced by their background in Washington Subways, Bay Area Rapid Transit in San Francisco & were keen Mumbai should adapt 1500 V DC Chopper system for the new stock without disturbing the OHE. It was an uphill task to change the mind-set of Washington technical WB hierarchy to a 25 kV AC system with DC 3 phase propulsion. I must give credit to the German consultants, who had the issue discussed by their superiors in Germany with their German Railway counter parts, got convinced of the efficacy of 25kV AC propulsion &stood their grounds with World Bank who finally relented.

On the Main Line side, two technologies for up-gradations on the Loco side took place quite closely towards the end of my career in IR. In the middle of 1988, import of a small fleet of 18 nos, 25kV Thyristor controlled DC motor Locomotives from ASEA Sweden & Japanese Group for Waltair Kirandul Line by the Board. I was CEE/E. Railway then & my colleague Late Dr Dorairaj who was CEE/S. E. Railway & who commissioned these locos on a difficult terrain was full of praise for these locos. In fact, SE Railway had successfully commissioned then thyristor controlled Capacitor Banks for Power Factor improvement on the Power Supply side & developed considerable ability on Thyristors. Waltair Elect Shed has done extremely well

During the end of my tenure in Board, in 1992, import of 3 Phase Locos-Passenger & Freight version, with regenerative capabilities from ABB was approved with a letter of intent. The case attracted considerable debate in the Parliament on the tender choice. The Govt, much later gave the project status of national importance & waived customs duty on the import which gave IR 50% relief on the cost. CLW successfully indigenised these Locos & the first Loco Nav Yug was inaugurated by the Hon’ble Minister for Railways Shri Nitish Kumar ji early 2000s as invited for the function by GM/CLW Sh Chidambaram. During the inauguration, Shri Nitish Kr mentioned it was strange he should be inaugurating the very loco whose order he had opposed in the Public Accounts Committee but was told the technology was very important to IR when he took over the Railways and & he was very happy at the indigenisation effort.

In my tenure on the Board, Computerized Control with ATP/ATS features was sanctioned for Calcutta Metro Train Communication Projects; additional Optic fiber projects were also sanctioned. Looking back, I felt Electrification has contributed considerably to Signalling & Communication technology up- gradation & Safety. Color light, Signalling, track circuiting, automatic signalling, use of axle counters, panel interlocking, optic fiber communication, etc. & together have enormously contributed to IR operational capabilities.

Delhi Metro needs to be congratulated for providing a State of the Art Metro for the National Capital & for a visionary decision to adopt standard gauge, later, falling in line with international practice; this will enable Indian Metros to gain quickly from technological up gradations globally which we could not do in IR being wedded to BG, which is non standard. Delhi Metro has also gone for an innovative 25kV overhead system of power collection, not withstanding large-scale use of underground tunnels. They have developed successfully a rigid contact system in the tunnels. The state of the art developments made in Metro stock, Traction distribution should prove quite useful to IR.

Looking ahead, I consider some of the challenges for IR would be:

1. Planning

OHE & TRD rehabilitation of the Civil Engineering Track renewals pattern, introducing more mechanization as many of the equipment in E & SE Railway are more than 50 years old &traffic block availability will be getting extremely restricted. It may be a good idea to introduce modern mechanized practices on a global level in RE projects first &later transfer these to maintenance. The old DC structures on C&W Railway suburban are getting 100 years old; there is a need for taking urgent total replacement. We have attempted piece meal replacements in the past. Corrosion of Steel stubs & falling of structures can pose serious safety hazard

2. IR needs to be congratulated for conceiving the Dedicated Freight Corridor as a technological up gradation approach in Freight operation, not merely adding parallel lines on existing tracks as relief lines. We need to factor in Energy Efficiency, Reliability & operational excellence in Electric Locos, OHE & Power Supply, and Signalling &Wagon stock. I am also told the new corridor will be laid adjacent to existing tracks & share even the Level crossings in Kanpur –Tundla high density section. As DRM/ALD way back in 83-87, we used to have several problems, even damages in not being able to open LC’s frequently & when opened, faces Road Traffic pressure. I think we need to include more ROB’s as a part of DFCC. The operation on 7.5 meter height contact system on western corridor for double Decker container operation on western corridor will be an interesting challenge.

3. I understand IR is contemplating 200 kmph up gradation on some of the existing lines. I happened to attend recently the International seminar of Inst. of Rolling Stock Engineers in Delhi & there were several interesting presentations. I also understand Delhi-Ahmedabad line is being proposed for High Speed electrification. If sanctioned, this project should suit for 200 kmph up gradation & OHE should also be so planned in advance.

Development of intercity EMUs, with so much of Electrification, should pay considerable dividends to IR. With Rolling Stock manufacturers already contributing to Metros, we should be able to get competitive bids.

4. With Indian Economy turning around, I feel there will be a strong case to introduce 300 kmph high-speed dedicated lines & perhaps Mumbai-Ahmedabad can immediately qualify with Delhi Mumbai industrial corridor coming up. I am sure IR will then consider Standard gauge as an important alternative.

5. I also feel there is a case for IR supporting an Urban Dev. Ministry initiative in setting up a very high-speed, short stretch between some Airport & city on magnetic levitation on the pattern of the Shanghai experiment in China.

6. One important area, Railway Engineers would need to focus would be skill development of its lowest & youngest rung of employees. I refer to unskilled employees, what Management Guru Prahlad calls the Bottom of the Pyramid. Skill building at this level emphasized in Govts. The decision to set up a National Skill Development mission in the country, is extremely important. We may have the problem of low educational attainments at the entry-level but let us spend money on organizing long induction & refresher courses for these entrants. It will pay immense dividends

7. With several new technological developments coming up, IR should look into greater Railway-Industry-Academia consortium approach in R&D areas like power inversion, Computer Software controls, power supply issues etc.

Before I conclude, I would like to compliment the present generation of Railway-Metro Engineers, in the audience who have made it possible for IR to join the Billion tonne loading club. Way back in early 90’s, we in Board felt very happy when we crossed the 500 MT target loading after tremendous efforts & used to feel that job of future generations in Railways will be extremely difficult, to surpass these targets in a big way unless the network is substantially expanded. On the other hand, I find Indian Railways have been steadily increasing loading, there has not been any substantial new Route kms. added except for some relief due to BG converted lines. I find GTKM handled on Elect Locos have increased from 9.2 Billion GTKM per RKM in 1992 to 20 Billion in 2011-12. The KMs per Elect. Loco failure has improved from 60000 km in 1992 to 375000 km in 2011-12, a remarkable effort. It speaks volumes of very high of continuous improvements taken by IR on various fronts.

Thank you to all

The lecture is posted on website with the kind consent of Shri N.Venkatesan, former Member Electrical.

.

You may also like:

- Saga of Traction for Iron Ore Transportation on SE Railway

- Optimized Algorithms For Effective Driving Of Tap Changer Controlled Electric…

- Case for compulsory periodic ‘Psychometric Testing’ of loco running staff

- Selection of Suspension Arrangement of Traction Motors : A Right…

- Electrical Multiple units (Train sets) for higher train speeds on…

- Technology Update on “Solid Lube Stick Wheel Flange Lubrication System”