How to be confident about safe use of electricity?

There are innumerable cases of fire and accidental death due to electrocution. What goes wrong and how it is not detected in time? Primarily there are two causes for this

- playing with the protection

- loose connection

- Protective system do operate correctly most of the time but there is a chance of protection failure at the critical time. Therefore second and third stage protection can only makes it full proof. When ever inspecting electrical installation, look for the system design of protection system and the redundancy inbuilt in the design. Sometime people complaint of not maintaining the protection system resulting into callousness. But I should say, protection system is maintenance free, it is only acting as a watch dog, monitoring the level of current with little duty cycle. It is the inbuilt design reliability which is important. Therefore, a manufacturer calling for maintenance as a pre-requisite for fail proof functioning, never accept it. In the procurement process itself, maintenance free sealed equipment shall only be considered. Two to three stage protection shall be inbuilt which can monitor over current with one or two stages, earth leakage, rate of rise of current, mho relay, pressure relay, thermal relay, differential relay etc..

- In earlier days, household protection was limited to fuse i.e. over current but installation of more and more power devices, has called for earth leakage monitoring device called RBCC relay. This provides alternate protection.

- Short circuits cannot be totally prevented from occurring but fires can be prevented by providing effective protection systems. Therefore blaming short circuit for a cause of fire is not correct. It is the failure of protection system.. Inspect any temporary connection taken at shamiana/tent house, short circuit of protection will invariable be seen. when questioned, the crude reply will be that we doing this since ages and nothing has happened.

- Inspect for earth that there is no discontinuity at any time. Earth resistance has not gone high.

As an Electrical Engineer, it is our responsibility to curb such thought process which has found rooted into our recent generation of technicians.

- Overheating is another cause of fire or smoke emission. Overheating takes place when there is a resistance in the path of a circuit which leads to its temperature rise. With increase in temperature, resistance goes up and again the temperature. Question is the temperature at which it stablises.

- In case there is some inflammable material nearby this over heated joint and its flash point is lower then the rise of temperature, fire and smoke is inevitable.

- Such failures can be prevented by

- Prohibiting use of inflammable material near any electricity carrying conductor, joint, junction board etc. There are many cases of violation of this, when some poor quality material finds application. The best test is just ignite the material and take assurance by your self about the dependability on the material in case of overheating any where in the conductor path. Need not wait for the sophistication of sending it to lab and then waiting for confirmation. Even with so much of harsh stricture by every one on the top, there are cases of using inflammable material even by reputed companies. There were recent cases of fire in power car equipped with well reputed diesel engine manufacturing company. One of the bellow used and located near turbo-charger was totally flammable and when ignited burnt like petroleum product. Below are some photograph of the mistakes, and it is very important to inspect for such mistakes and take immediate action. ” chalta ha approach’ or ‘jugad technology’ need to be curbed with firm hand

.

- Prohibiting use of inflammable material near any electricity carrying conductor, joint, junction board etc. There are many cases of violation of this, when some poor quality material finds application. The best test is just ignite the material and take assurance by your self about the dependability on the material in case of overheating any where in the conductor path. Need not wait for the sophistication of sending it to lab and then waiting for confirmation. Even with so much of harsh stricture by every one on the top, there are cases of using inflammable material even by reputed companies. There were recent cases of fire in power car equipped with well reputed diesel engine manufacturing company. One of the bellow used and located near turbo-charger was totally flammable and when ignited burnt like petroleum product. Below are some photograph of the mistakes, and it is very important to inspect for such mistakes and take immediate action. ” chalta ha approach’ or ‘jugad technology’ need to be curbed with firm hand

- Use of cables is very common for transporting power from one place to another. Cable failure in conjunction with failure of earth leakage protection leads to smoke emission and fire. Insulation failure generally takes place at

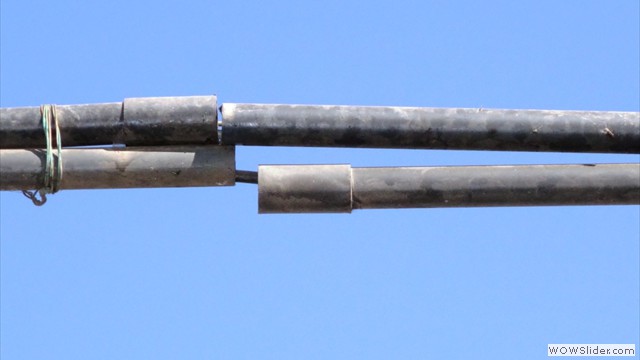

- Location of pressure point developed at the place of securing by clamps. Sharp edges of clamp, cleats having sharp edges exert high pressure point on the cable and results in its rupturing. Fibeglass cable cleats has recently be introduced for securing under slung alternator cable of AC/TL coach and observe the sharp edges. There is no doubt that cable failure of these alternator is one of the major reason for sick marking.

- Sharp bending of cable develop point of concentration of high stresses as well as fatigue. Sharp corners shall be avoided.

- Touching of cable with sharp corners of metallic or non-metallic bodies. Maintain physical gap and avoid habit of providing insulating material to fill up the gap. Any solid body will damage the insulation.

- Cables at the junction when not cleated properly and not tightly secured. It is the contact pressure important for the purpose of transfer of current instead contact area. Be careful to ensure contact pressure for any joint

- When cable transfer power from vibrating plane to fixed plane e.g. from locomotive body to traction motor mounted on bogie. It is observed that cable strands at the point of entrance into the socket get work hardened resulting into its breakage. The duty cycle makes the life of cable at such location half of the natural life of cable.

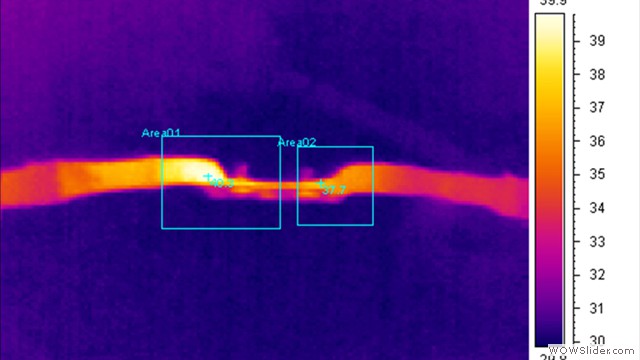

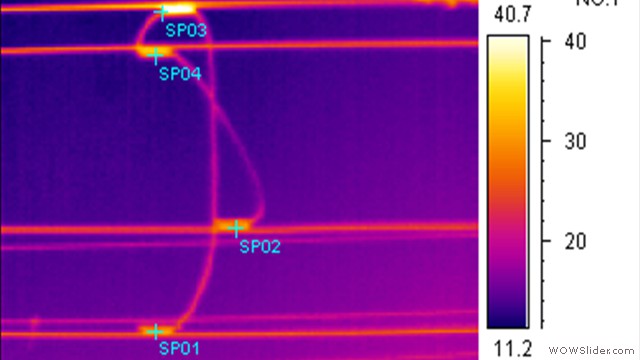

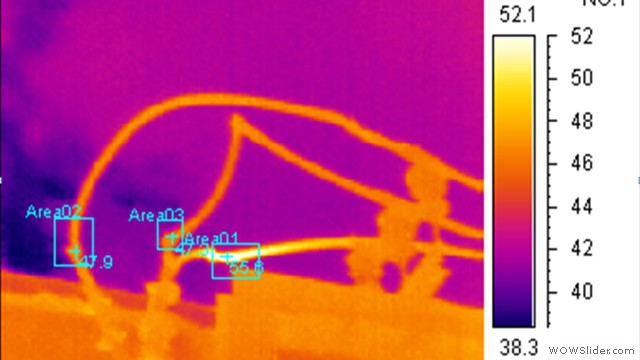

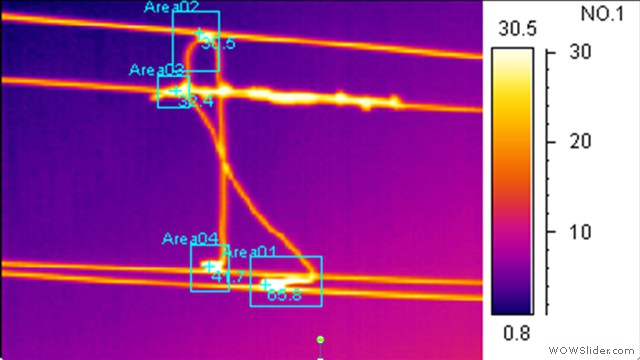

- Even after taking all precautions there is every possibility of a contact getting loosened. Condition monitoring techniques are available using thermal imaging of the contact from distance helping identifying the defect before failure. This is followed in DC system very sincerely as the current handled by jumpers and contact is in the range of 5000A and helped in identifying defects. Indian Railways shall consider its use for monitoring the temperature at vulnerable locations which are not easily approachable to check the tightness.

You may also like:

- Understanding electical cable and and its role in fire

- Electrical Protection System – Tap Changer Locomotive

- Electrical accidents waiting to happen…

- Indian Electricity Rules, 2005 defines the basic fundamentals of Electricity…

- ‘EARTHING’, a must for every one to understand its importance…

- Electrical Protection System -Train Lighting and Air Condtioning

1

1 2

2 3

3 4

4

1

1 2

2 3

3 4

4 5

5 6

6 7

7 8

8 9

9 10

10 11

11 12

12 13

13

1

1 2

2 3

3 4

4 5

5